Plastic Push Screws

Send Inquiry

The plastic push screws have different surface treatments to make it look better and last longer. Common plating choices are things like bright nickel, matte black, antique brass, or gold finishes. These not only resist rust but also look good with different lanyards or product designs.

Some versions might have epoxy coatings or colored paint. These finishes don’t just let you change how it looks,they also add an extra layer of protection against tarnishing, scratches, and stuff from the environment.

Size

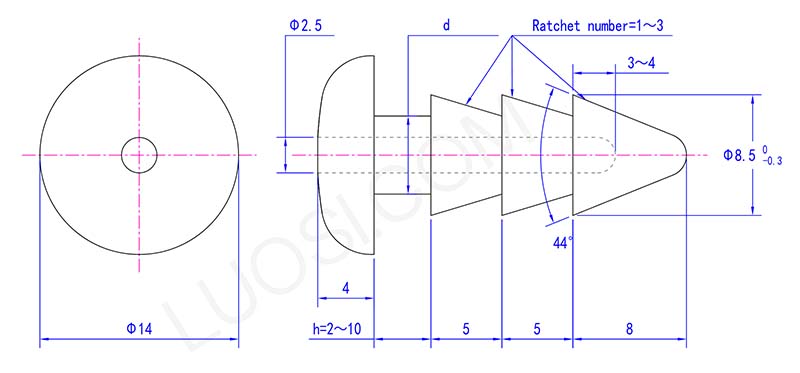

Even though there are small differences, the plastic push screws usually stays around standard small sizes.

Typically, the frame is about 25mm wide (that’s 1 inch), around 15mm tall, and 6-8mm thick. The card slot is sized just right for the corners of standard plastic cards, like CR80 ones.

This consistent size means it works with cards made in bulk and lanyard attachments. The small size of the Type E card buckle is a key thing,it lets it be used in places where space is tight.

| Mon | Φ6 |

| d max | 6 |

| d min | 5.5 |

Materials

Q:What materials are used in manufacturing the plastic push screws?

A:The standard plastic push screw is made from strong, long-lasting polyamide Nylon 66, basically. That means it holds up well against wear, hits, and stress from the environment.

If you need something specific, we can also make the Type E card buckle from PP or ABS. We can even add metal parts to reinforce it, if that’s what you need.