Expanding Rivet Clips Push Type

Send Inquiry

The base material already gives good protection, but certain surface treatments can make the expanding rivet clips push type even better.

Adding color through masterbatch pigments when molding is common,it helps tell apart different sizes or specs easily. Some types have built-in UV stabilizers, which work well for long-term outdoor use.

Unlike metal pins, the plastic split pin body doesn’t need electroplating or galvanizing. The main polymer itself has enough natural resistance to handle the environment.

Available sizes

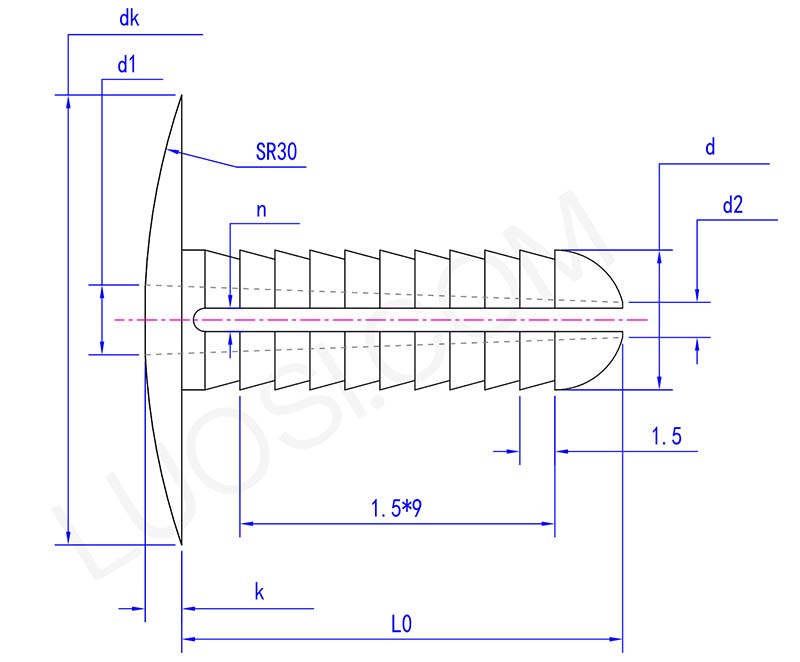

The size of a expanding rivet clips push type is usually given by the shank’s diameter and length. They follow standard metric sizes,like 2mm*20mm, 3mm*30mm or imperial ones, such as 1/16" *3/4", 3/32"*1".

The split design gives a bit of flexibility, so it can fit slight differences in hole sizes.

They come in various diameters and lengths, which means they work for lots of different weight needs and assembly thicknesses.

Mon

Φ6

Φ8

Φ10

d max

6

8

10

d min

5.8

7.8

9.8

dk max

16.2

16.2

18.2

dk min

15.8

15.8

17.8

k max

1.6

1.6

2.1

k min

1.4

1.4

1.9

L0

20

20

22

d1

3

4

5

d2

1.5

2

3

n

1

1

1.5

Corrosion resistant

Q:How does the corrosion resistance of your expanding rivet clip push type compare to metal cotter pins, especially in harsh or marine environments?

A:Our expanding rivet clips push type won't rust or corrode. Metal cotter pins are susceptible to rust, corrosion, and potential adverse reactions with other metals. Our plastic version, however, is unaffected by moisture, salt spray, various chemicals, and acid and alkali solutions.

So, it's perfect for places where stuff normally eats away at metal. Think boats (marine stuff), chemical plants, outdoor gear,anywhere corrosion is a headache. Basically, the expanding rivet clip push type lasts longer and stays reliable. You won't get pins seized up or weakened just because of the environment they're in.