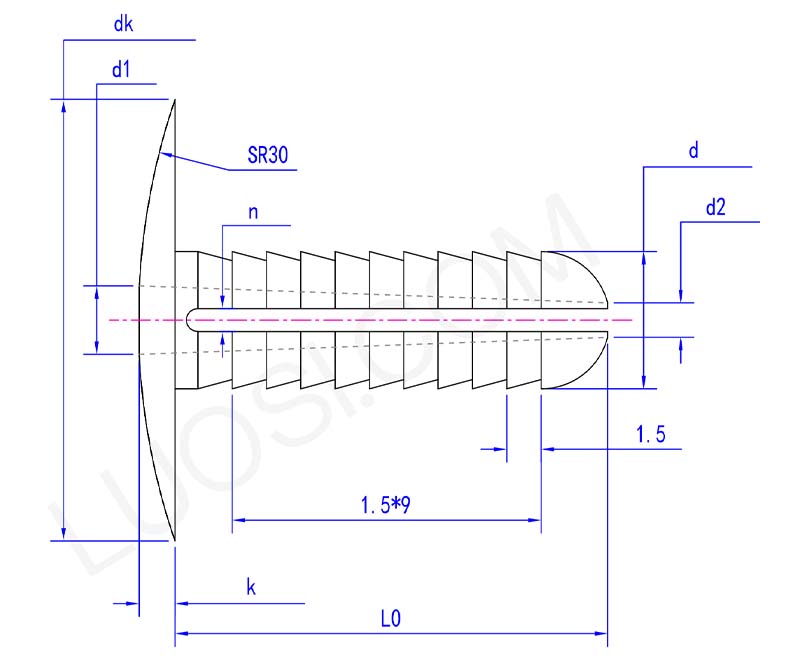

Expanding Rivet Clip Retainer

Send Inquiry

|

Mon |

Φ6 |

Φ8 |

Φ10 |

|

d max |

6 | 8 | 10 |

|

d min |

5.8 | 7.8 | 9.8 |

|

dk max |

16.2 | 16.2 | 18.2 |

|

dk min |

15.8 | 15.8 | 17.8 |

|

k max |

1.6 | 1.6 | 2.1 |

|

k min |

1.4 | 1.4 | 1.9 |

|

L0 |

20 | 20 | 22 |

|

d1 |

3 | 4 | 5 |

|

d2 |

1.5 | 2 | 3 |

|

n |

1 | 1 | 1.5 |

The expanding rivet clip retainer is a useful plastic fastener. It works as a safer, lighter option that resists rust, instead of the usual metal cotter pins.

It’s basically a cylindrical piece with a split down the middle. You put it through a pre-drilled hole, then bend the two legs out to hold parts like clevis pins, shafts, or linkages in place.This plastic version gets rid of problems like metal getting worn out, sharp edges, and galvanic corrosion.

Advantages

The main upsides of the expanding rivet clip retainer is about safety, being lighter, and holding up in different environments.

Unlike metal pins, it doesn’t have the problem of sharp burrs that could cut you when putting it in or taking it out. It’s way lighter, which matters a lot for aerospace and car uses.

What’s more, the expanding rivet clips retainer naturally resists rust and corrosion. It can be used in wet locations, around chemicals, or where electricity is insufficient, and where metal needles may malfunction or cause problems.

Maximum load capacity or shear strength

The specific value of the shear strength of our expanding rivet clip retainer will vary depending on the diameter of the pin and the specific material grade.

It’s designed to handle a lot of vibration and moving loads, which are common in machinery, car parts, and assembly lines.

The material naturally has some flexibility and springiness, which helps it absorb shocks. That makes it a reliable replacement for metal pins in many tough environments,it doesn’t wear out easily, and it also lessens wear on the parts it connects.