Expanding Rivet Clips Push Type Retainer

Send Inquiry

Plastic materials made for tough use, like Nylon 6/6 or Acetal (POM), are what make up the high-performance expanding rivet clips push type retainer. These materials are pretty strong when pulled and can take hits, especially considering how light they are.

What’s important is they hold up well against lots of chemicals, solvents, fuels, and salt water. Also, the plastic split pin body naturally doesn't conduct electricity. That means it stops galvanic corrosion from happening when used with different kinds of metals,something metal pins can't avoid.

Application

The expanding rivet clips push type retainer gets used a lot in different industries.

Common uses include holding clevis pins in control linkages, keeping wheel axles on carts and trolleys in place, locking castle nuts on assemblies that aren’t super critical, and fastening panels on marine or outdoor equipment.

Since it doesn’t scratch things and doesn’t conduct electricity, it works really well for electronics assembly, food processing machines, and situations where you need to keep EMI/RFI shielding working right.

Tolerable temperature range

The regular expanding rivet clips push type retainer is made from polymers that hold up well in different temperatures. It usually works reliably when used continuously between -40°C and 120°C,that’s -40°F to 248°F. Some high-temperature versions can handle higher temps than that.

Within this range, the split pin keeps its springy tension and stays the right size, so it stays in place securely.

If you need it for really extreme conditions outside this range, we have special material options. Just ask about your specific temperature needs, and we’ll find the best split pin body for you.

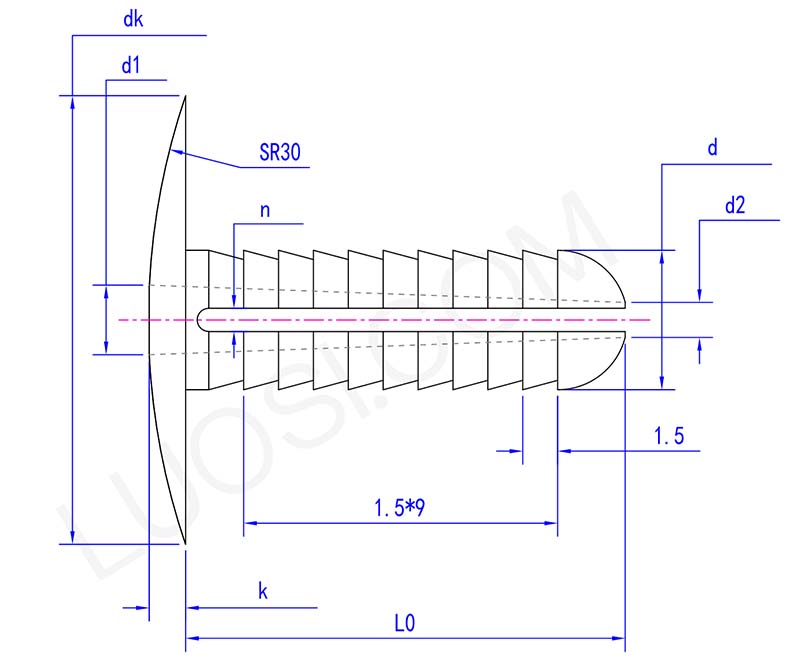

|

Mon |

Φ6 |

Φ8 |

Φ10 |

|

d max |

6 | 8 | 10 |

|

d min |

5.8 | 7.8 | 9.8 |

|

dk max |

16.2 | 16.2 | 18.2 |

|

dk min |

15.8 | 15.8 | 17.8 |

|

k max |

1.6 | 1.6 | 2.1 |

|

k min |

1.4 | 1.4 | 1.9 |

|

L0 |

20 | 20 | 22 |

|

d1 |

3 | 4 | 5 |

|

d2 |

1.5 | 2 | 3 |

|

n |

1 | 1 | 1.5 |