Handle Thread Star Nuts

Send Inquiry

Yes, each batch of Handle Thread Star Nuts must undergo final inspection before shipment.

We will randomly select samples for two types of tests: destructive tests and non-destructive tests. This includes torque and tensile strength tests, salt spray tests (to check the durability of the coating), and a careful visual inspection of the driving grooves.

This strict final inspection ensures that the star-shaped nuts can function properly and meet all required standards. So you can rest assured that the products you receive are of high quality and you can trust them.

Comply with international standards

We produce Handle Thread Star Nuts under the ISO 9001 quality management system - thus we have obtained the relevant certifications. If you need material certifications (such as Class 3.1 certification), please let us know and we will provide them for you.

Our products meet international standards, such as ISO (take torque screws for example, they must comply with ISO 10664) and DIN standards. These certifications provide you with direct proof that we have never relaxed our control over quality and are committed to ensuring the same quality of every service/product. They also ensure that star nuts can perform well in important applications in regulated industries (such as automotive and aerospace). In these fields, being able to trace the products and ensure their high quality is of crucial importance.

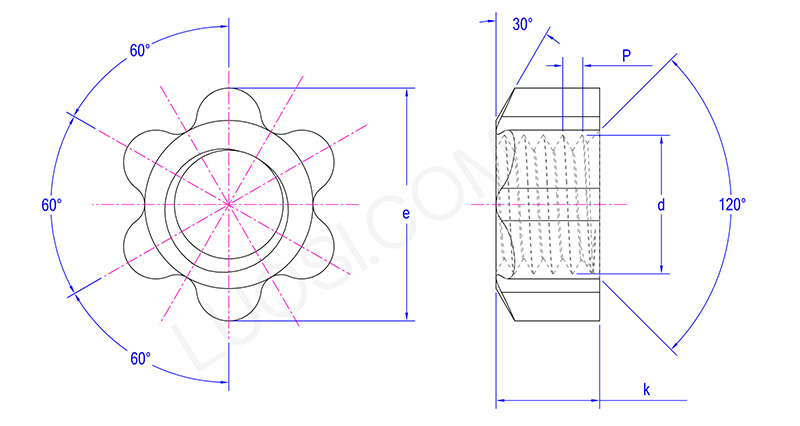

Product Parameters

| Mon | M1.4 | M1.6 | M1.7 |

| P | 0.3 | 0.35 | 0.35 |

| e max | 2.8 | 2.8 | 2.8 |

| e min | 2.66 | 2.66 | 2.66 |

| k max | 1.1 | 1.1 | 1.1 |

| k min | 0.9 | 0.9 | 0.9 |

FAQ

Q: Can Handle Thread Star Nuts be used in high-vibration environments?

A:Standard Handle Thread Star Nuts work great for most jobs, but they might come loose if there’s a lot of vibration.

If you’re dealing with that kind of situation, we suggest our Professional-Grade Star shape nuts with a nylon insert or prevailing torque—they have a locking feature. These special star nuts don’t loosen easily, so they’re good for things like cars or machinery, where vibration is a problem.