Round Knobs With Collar Rolling Nut

Send Inquiry

First, drill a hole in the sheet metal that matches the Round Knobs with Collar Rolling Nut’s size. Don’t make the hole too big—otherwise, it won’t lock properly. Clean out any metal shavings left in the hole; they might get in the way of installation.

Then place the nut into the pre-drilled hole, making sure it sits flat against the sheet. Use a standard press tool with a die that fits the nut’s top. Apply steady, even pressure to the tool—you’ll feel a slight “click” when it’s locked in place. Hold the pressure for 1-2 seconds to make sure it’s secure.

Avoid using hammer blows; this can bend the nut or damage the sheet metal. It works best on thin to medium sheet metal (0.5-2mm thick). Once installed, you can screw in a bolt smoothly without the nut spinning. Round Knobs with Collar Rolling Nut is easy to use even for beginners, no complicated skills needed.

Product Packaging

We use simple, practical packaging to keep the nuts safe. For small orders or samples, they’re packed in clear plastic bags—usually 100 or 200 pieces per bag. Each bag has a basic label with size, material, and batch number, so you can find what you need easily.

Bulk orders go into sturdy cartons. Depending on the nut size, each carton holds 5000 to 10000 pieces. We put foam or bubble wrap inside to stop them from scratching or moving around during shipping. The cartons have clear marks for handling, like “keep dry” or “no stacking heavy things.”

If you need custom packaging—like your logo on bags or a specific quantity per pack—just let us know when ordering. No extra fancy stuff, just what works for storage and shipping. It comes in these standard options, which fit most small workshops, big factories, or DIY users’ needs.

Q&A Session

What thickness of sheet metal is suitable for Round Knobs with Collar Rolling Nut?

A:It works best on thin to medium sheet metal, with a thickness range of 0.5mm to 2.5mm. Too thick metal won’t let it lock properly, and too thin may deform during installation. Common materials like cold-rolled steel, aluminum, and stainless steel sheets are all okay. Just make sure the pre-drilled hole size matches the nut’s outer diameter—we can provide a size chart if you need it for reference.

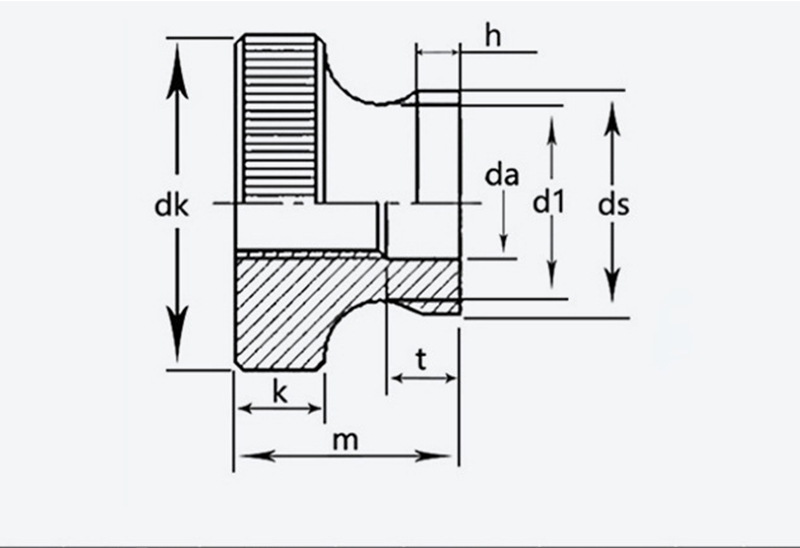

| size | Pitch | Outer diameter | Height | k | ds | da | d1 | T | h | ||||

| max | min | max | min | max | min | max | min | max | |||||

| M3 | 0.5 | 11 | 10.7 | 7 | 6.64 | 2.8 | 6 | 5.7 | 3.5 | 3.2 | 5.2 | 2 | 1.2 |

| M4 | 0.7 | 12 | 11.7 | 8 | 7.64 | 3 | 8 | 7.64 | 4.5 | 4.2 | 6.4 | 2.5 | 1.5 |

| M5 | 0.8 | 16 | 15.7 | 10 | 96.6 | 4 | 10 | 9.64 | 5.5 | 5.5 | 9 | 3 | 2 |

| M6 | 1 | 20 | 19.7 | 12 | 11.6 | 5 | 12 | 11.6 | 6.56 | 6.2 | 11 | 4 | 2.5 |

| M8 | 1.25 | 24 | 23.7 | 16 | 15.6 | 6 | 16 | 15.6 | 8.86 | 8.5 | 13 | 5 | 3 |

| M10 | 1.5 | 30 | 29.7 | 20 | 19.5 | 8 | 20 | 19.5 | 10.9 | 10.5 | 17.2 | 6.5 | 3.8 |