Black Nickel Plating Rolling Nut

Send Inquiry

The most common choice is the Black Nickel Plating Rolling Nut made of carbon steel.. It’s strong enough for regular sheet metal jobs, like furniture assembly or small equipment fixes. Most carbon steel ones have a zinc plating to keep rust away, which works well for indoor use or covered outdoor spots.

For damp environments or outdoor use, stainless steel is a better option. It holds up against moisture and corrosion, even in slightly salty areas near the coast. We also have aluminum versions for lightweight needs—mostly used in electronics, where heavy parts might affect the device’s performance.

All materials meet basic industry standards, no extra unnecessary treatments. Pick carbon steel for daily tasks, stainless steel for wet places, and aluminum for light-duty work. Black Nickel Plating Rolling Nut’s material options cover most common assembly needs, no fancy add-ons just practical choices.

Product surface treatment

Zinc plating is the most common option. It’s a basic process that helps prevent rust, good for indoor use or covered outdoor spots. It doesn’t add extra thickness, so it won’t affect how the nut fits into the sheet metal hole during installation. Most daily-use nuts come with this treatment.

For better corrosion resistance, there’s hot-dip galvanizing. It’s thicker than regular zinc plating, so it holds up longer in humid areas or places with slight moisture, like workshops near the coast. For stainless steel nuts, we do passivation treatment—it just boosts their natural rust-proof ability without changing their look.

No fancy coatings here, just practical ones. Pick zinc plating for standard needs, hot-dip galvanizing for damp environments, and passivation for stainless steel models. Black Nickel Plating Rolling Nut’s surface treatments are all about basic protection, fitting most common sheet metal assembly scenarios.

Q&A Session

Q: Can I install it without professional tools?

A:No, you need a basic press tool or a small riveting machine. Manual hammering isn’t recommended; it will damage the nut’s threads or make it loose. For small batches, a handheld manual press tool works. For large orders, an automatic press machine is more efficient. We can also recommend tool models that fit our products if you don’t have the right one yet.

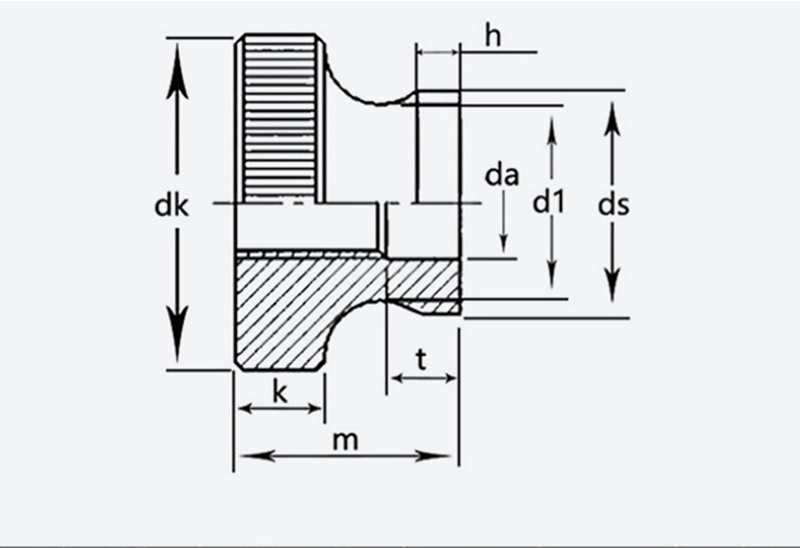

| size | Pitch | Outer diameter | Height | k | ds | da | d1 | T | h | ||||

| max | min | max | min | max | min | max | min | max | |||||

| M3 | 0.5 | 11 | 10.7 | 7 | 6.64 | 2.8 | 6 | 5.7 | 3.5 | 3.2 | 5.2 | 2 | 1.2 |

| M4 | 0.7 | 12 | 11.7 | 8 | 7.64 | 3 | 8 | 7.64 | 4.5 | 4.2 | 6.4 | 2.5 | 1.5 |

| M5 | 0.8 | 16 | 15.7 | 10 | 96.6 | 4 | 10 | 9.64 | 5.5 | 5.5 | 9 | 3 | 2 |

| M6 | 1 | 20 | 19.7 | 12 | 11.6 | 5 | 12 | 11.6 | 6.56 | 6.2 | 11 | 4 | 2.5 |

| M8 | 1.25 | 24 | 23.7 | 16 | 15.6 | 6 | 16 | 15.6 | 8.86 | 8.5 | 13 | 5 | 3 |

| M10 | 1.5 | 30 | 29.7 | 20 | 19.5 | 8 | 20 | 19.5 | 10.9 | 10.5 | 17.2 | 6.5 | 3.8 |