Lengthened Cylindrical Knurled Nut

Send Inquiry

If you need customs clearance or project filing certificate for Lengthened Cylindrical Knurled Nut, we can provide them for free. The certificate is nothing fancy, just the necessary details: batch number, type of metal material, surface treatment method, key test results.

Test results include thread accuracy checks and knurled ridge firmness testing to ensure the threads mate smoothly with standard bolts and that the ridges will not wear out easily. Each certificate has a unique traceability number so you can look up production information if needed. It is a simple document with straightforward terms. Lengthened Cylindrical Knurled Nut is available with this certificate; just mention your request when placing your order and we will include it in the shipment.

Product Uses

This nut is mainly for scenarios where you need tool-free twisting. It’s super common in small tools—like screwdrivers with replaceable bits, where you twist it to lock the bit in place. It also works for electronic devices, such as covering ports or securing small components that might need occasional adjustment.

For DIY projects, it’s great for things like custom hobby models, small wooden crafts, or homemade gadgets. In light industrial settings, it’s used for adjusting parts on small machinery or securing panel covers that need frequent access. It fits most standard small bolts and works best for light loads. Lengthened Cylindrical Knurled Nut is all about easy hand operation, making it a go-to for jobs where tools are inconvenient or unnecessary.

Q&A Session

Q:How do you pack them for bulk orders? Will the ridges get scratched during shipping?

A:For bulk orders, we use thick cardboard boxes with dividers inside. Each nut is either in small plastic bags or separated by paper dividers to prevent them from rubbing against each other. This stops the ridges from getting scratched. We also add a moisture-proof layer in the box to prevent rust. We’ve shipped thousands of bulk orders before, and scratch issues are rare. If you receive any scratched pieces, send us photos, and we’ll replace them for free.

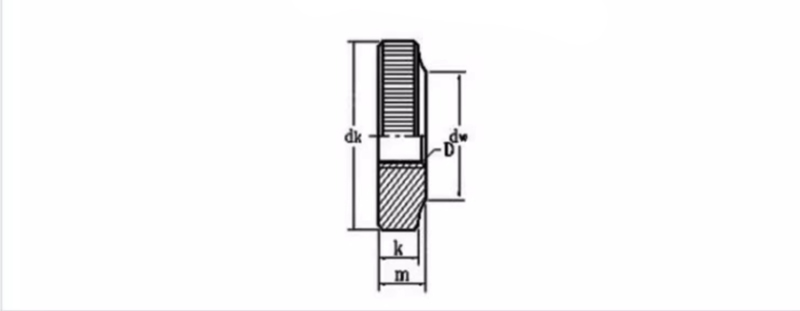

| D | P | dk | m | Every 1,000 unitsn terms ofweight≈kg | ||

| max | min | max | min | |||

| M1.5 | 0.3 | 6 | 5.78 | 2 | 1.75 | 0.31 |

| M1.6 | 0.35 | 7 | 6.78 | 2.5 | 2.25 | 0.56 |

| M2 | 0.4 | 8 | 7.78 | 2.5 | 2.25 | 0.73 |

| M2.5 | 0.45 | 9 | 8.78 | 3 | 2.25 | 0.91 |

| M3 | 0.5 | 11 | 10.73 | 3 | 2.75 | 1.69 |

| M4 | 0.7 | 12 | 11.73 | 4 | 2.75 | 1.98 |

| M5 | 0.8 | 16 | 15.73 | 5 | 3.7 | 4.96 |

| M6 | 1 | 20 | 19.67 | 6 | 4.7 | 9.23 |

| M8 | 1.25 | 24 | 23.67 | 6 | 5.7 | 16.4 |

| M10 | 1.5 | 30 | 29.67 | 8 | 7.64 | 32.36 |