Screw Thread Inserts

Send Inquiry

Screw Thread Inserts fix damaged threads or strengthen weak threaded holes. Why use 'em? To repair stripped threads, make things way stronger in soft materials (think aluminum or plastic), and give you reusable threads that hold up. They're usually brass (rust-resistant) or strong stainless steel. Many have zinc or nickel plating to fight corrosion.

It comes in loads of metric and imperial sizes, which is why you see them everywhere in auto, aerospace, and electronics. Installing them correctly is key, but once they're in, just maintain them like regular fasteners – nothing special. Basically, if you need to fix or reinforce threads, grab some inserts.

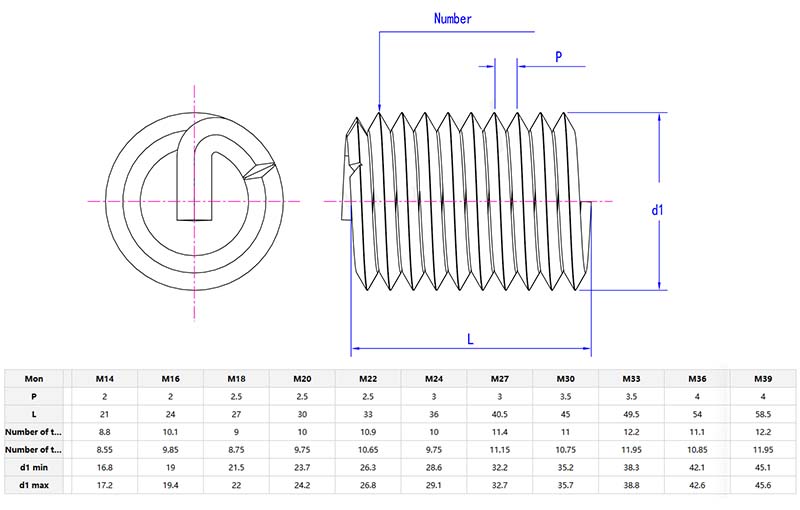

Product details and parameters

Screw Thread Inserts are designed for longevity. They turn flimsy threads into sturdy connections. How? By adding tougher metals (like 303/304 stainless or phosphor bronze) into softer materials. Surface-wise, many have cadmium for rust protection or a dry lubricant to make screwing things together smoother.

This come in heaps of precise sizes – coarse/fine threads, various lengths – fitting nearly any hole you've tapped. That's why they're used in engines, machinery, and everyday items: they prevent thread wear or failure. Maintenance? Just check for gunk or damage when changing fasteners. Bottom line: they're an easy way to make threaded joints hold up over time without constant attention.

FAQ

Q: Why should I choose this over a cheaper helical coil insert (like a Helicoil)?

A: Screw Thread Inserts generally hold up better than helical spring types:

The diamond coil shape spreads the load better and handles repeated stress more effectively.

Their design makes them less likely to loosen from vibration.

While both fix threads, a Screw Thread Insert usually gives a tougher, longer-lasting connection – especially for critical jobs involving frequent assembly/disassembly or heavy loads. That's why the extra cost often makes sense.