External Force Cutting Anchor

Send Inquiry

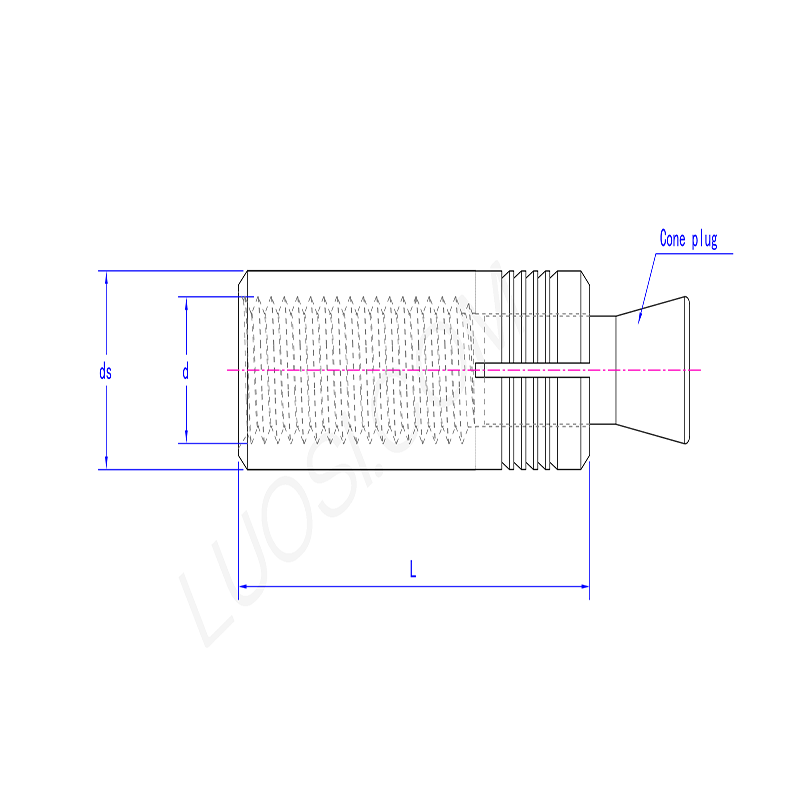

The external force cutting anchor is mainly composed of parts such as the screw and the expansion sleeve. They are widely used. If you use them to fix things, you don't have to worry about rusting. It can firmly fix the components to the building structure.

Product parameters

| Mon | M6 | M8 | M10 | M12 | M16 |

| P | 1 | 1.25 | 1.5 | 1.75 | 2 |

| ds | 10 | 12 | 12 | 18 | 22 |

Features

External force expansion cutting anchor uses external force to anchor anchor bolts in concrete or masonry structures. Drill holes, insert bolts, and then tighten the nuts with a wrench. During the tightening process, pull the conical end into the expansion sleeve to squeeze the hole wall outward. The grip force of the sleeve generates the holding force. It is a mechanical anchor bolt that is activated by the force of a wrench.

The "External force" in "external force cutting anchor" refers to the expansion force provided after insertion. You don't need to tap it with a hammer like some bolts to make it expand. Instead, external force is applied by tightening the nut with a wrench. This controlled tightening action directly causes the sleeve to expand and grip tightly.

You can use the external force expansion cutting anchor to fix the object to a solid concrete, brick or block wall/floor. Common tasks include fixing mechanical bases and structural steel columns to foundations, pipe supports, handrail columns or heavy-duty shelf supports. They are suitable for medium to heavy-load environments that require reliable post-pouring mechanical anchoring.

Install

The external force cutting anchor is easy to operate and quick to install. First, drill a hole in the wall or on the ground, put the anchor bolt in, and then tighten the nut. Its expansion sleeve will spread out and be firmly fixed. It can bear a large weight and firmly fix things in scenes such as concrete and natural hard stone.