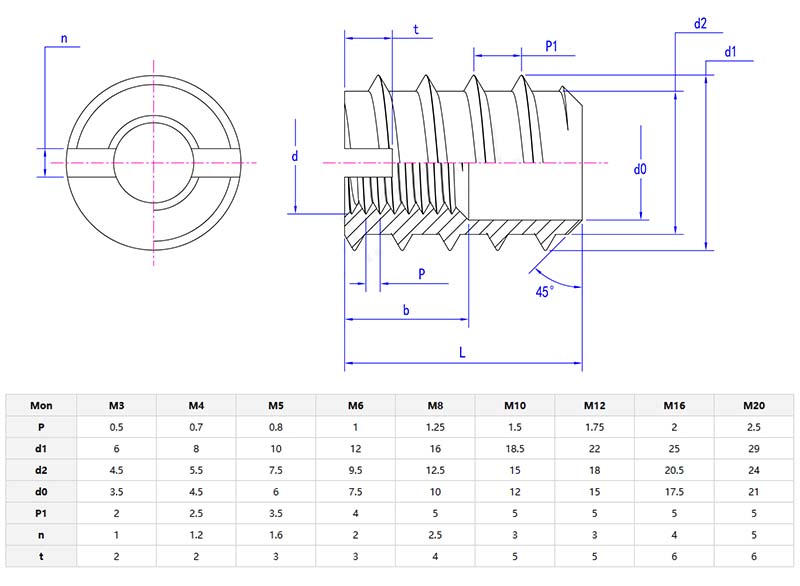

Screwed inserts

Send Inquiry

Screwed inserts are helical coil made from diamond-shaped wire. It’s designed to create strong internal threads in softer materials or when the original threads are damaged. You put it into a pre-tapped hole, and it gives a tough, long-lasting threaded surface that makes the assembly last longer. The screwed insert works like a permanent sleeve— it spreads out the pressure evenly and stops threads from stripping or getting damaged. This is a practical solution for secure fastening in tough situations where the base material isn’t strong enough.

Product details and parameters

The main advantage of screwed insert is they can fix and strengthen stripped or weak threads, which saves you from having to replace parts that cost a lot. They boost pull-out and shear strength way more than just the base material by itself. Putting in a screwed insert isn’t too hard—you can do it with regular tools. Also, they hold up well against vibration, stop different metals from corroding each other, and make sure the threads stay consistent and can be used again. That makes screwed inserts a smart choice if you want something reliable without spending too much.

FAQ

Q: How does this actually create a stronger thread compared to just tapping the base material?

A: A Screwed inserts goes into a pre-drilled and tapped hole that’s a bit bigger than usual. The coil is made from diamond-shaped wire, which gives it a lot more surface area to hold the load and spreads out the stress evenly along the threads. This helps prevent the softer base material from stripping, getting damaged, or wearing out when there’s vibration or heavy use. The result is a strong, long-lasting threaded connection that’s way better than regular tapped threads, especially in soft metals or plastics.