Weld studs

Send Inquiry

The weld studs are unique because it creates a durable, strong connection to the underlying structure. Unlike threaded bolts, which require a nut, one end is specially prepared for welding (often with a ring or a specialized tip). The other end is often threaded, allowing for a nut to be secured or used directly as a mounting point. In heavy industrial operations, where strength, speed, and reliability are crucial, these parts are essential for efficient assembly. They streamline production lines and are designed to work well with automatic or semi-automatic stud welding.

Principle and application:

The main purpose of the welded studs is to create a strong, non-detachable connection point on the base material so that it can extend directly from the base part. After welding, the threaded end allows you to quickly and safely fix other components such as panels, wiring harnesses, insulation layers or pipe supports. This way, there is no need to drill, tap or touch the back of the workpiece. This stud is very useful in places with limited space and when thin metal sheets are difficult to install securely.They work better than regular fastening methods in these cases.

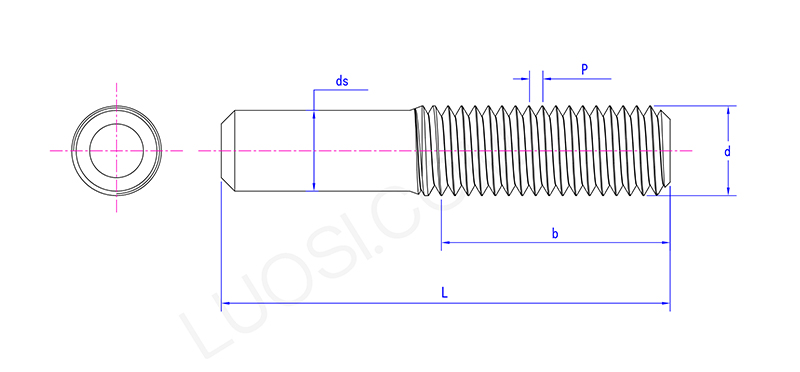

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| ds | 4.48 | 5.35 | 7.19 | 9.03 |

10.86 |

12 |

14.7 |

Material grade:

Our weld studs usually come in carbon steel,like ASTM A29,stainless steel (304 or 316), and aluminum. If you need them to really hold up against rust, 316L stainless steel ones are a good bet. We can also get you special alloys if you ask. We always have material certifications (MTRs) available, so you know they meet international standards for whatever you need to use them for.