Heavy duty Threaded Rod

Send Inquiry

We’ve got different materials for our Heavy duty Threaded Rods—so they work for different uses and environments. The most common one is carbon steel. It’s good for most regular industrial jobs, priced fairly, and holds enough weight.

If you’re worried about rust, go for 304 or 316 stainless steel. These work well in damp places, outdoors, or areas with chemicals—like coastal equipment or food processing machines.

We also offer alloy steel as a material. This material is more robust when subjected to force and is more suitable for applications such as structural support or heavy machinery that needs to withstand significant pressure. If you require non-magnetic material, brass is also an option. They are commonly used in electrical equipment or precision instruments that are sensitive to magnetic fields.

Product surface treatment

We’ve got different surface treatments for our Heavy duty Threaded Rods—they help the rods last longer and resist rust, so they work in different environments. The most common one is galvanization. It’s affordable, gives basic rust protection, and works for indoor use or mild outdoor conditions.

If the environment is harsher—like near the coast or in industrial areas—we suggest hot-dip galvanizing. This coating is thicker and holds up better, so it can handle moisture and chemicals.

For stainless steel ,you can go with passivation treatment. It gets rid of surface impurities to make the material’s own corrosion resistance better. Black oxide treatment boosts wear resistance and leaves the surface with a matte black look—good for mechanical parts that need to be durable but also look decent.

If you have special needs—like for high-precision equipment or the aviation industry—chemical nickel plating is an option too. It forms a uniform, hard coating that’s really good at resisting corrosion.

Q&A Session

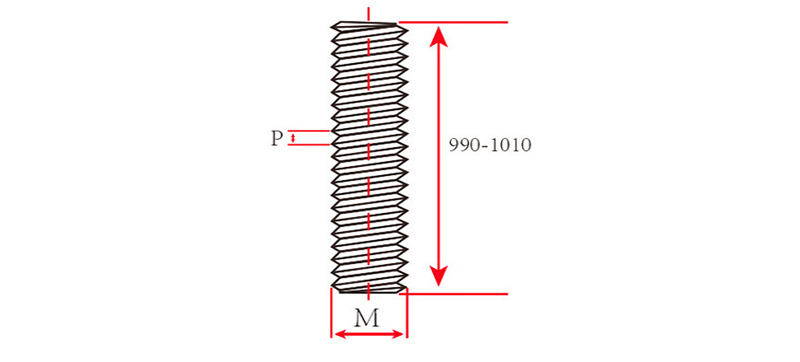

Q: What thread standards and types do you provide?

A:Our Heavy duty Threaded Rod is mainly produced to ISO Metric (e.g., M6, M10) and UNC/UNF standards. We offer full-size threaded rods as the standard configuration. Additionally, we can provide custom-length threaded rods according to the specific dimensions of your project.

| D | P | D | P | D | P |

| M3 | 0.5 | M14 | 2 | M30 | 3.5 |

| M4 | 0.7 | M16 | 2 | M33 | 3.5 |

| M5 | 0.8 | M18 | 2.5 | M36 | 4 |

| M6 | 1 | M20 | 2.5 | M39 | 4 |

| M8 | 1.25 | M22 | 2.5 | M42 | 4.5 |

| M10 | 1.5 | M24 | 3 | M45 | 4.5 |

| M12 | 1.75 | M27 | 3 | M48 | 5 |