Versatile Internal Thread Weld Studs

Send Inquiry

Besides regular rust protection, versatile internal thread weld studs can get special finishes. For example, stainless steel nuts can be phosphated to ensure excellent rust resistance. Aluminum studs can be electroplated with nickel, creating a protective film on the surface through electrolysis, significantly increasing the corrosion resistance and service life of the parts. We also apply a special lubricant to the threads to prevent galling and seizure during installation.

Follow standards:

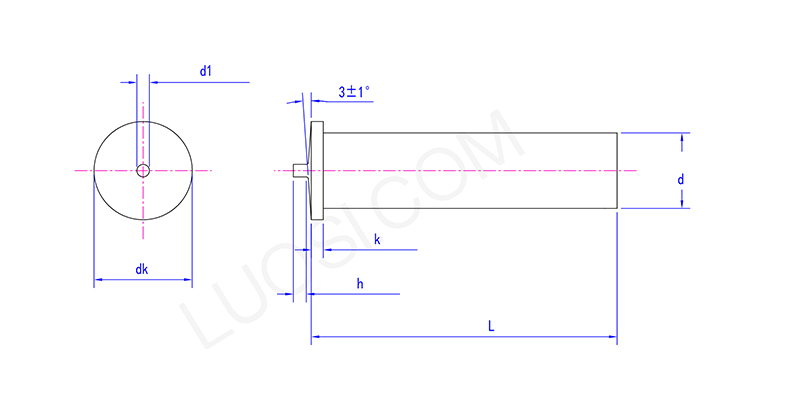

Versatile internal thread weld studs follow international standards like ISO 13918. That covers things like sizes, materials, and testing. It sets out thread sizes,common metric ones go from M3 up to M30 and bigger, and imperial sizes like 1/4"-20 or 3/8"-16 are pretty common too. There’s also info on lengths, the diameter of the weld base, and chamfer details. These standards make sure studs can be swapped out if needed and work like you’d expect. The main measurements to note are thread length, total length, weld base diameter, and the specific end design for welding,like drawn arc or CD tips.

| Mon |

Φ3 |

Φ4 |

Φ5 |

Φ6 |

| d max | 3.1 | 4.1 | 5.1 | 6.1 |

| d min | 2.9 | 3.9 | 4.9 | 5.9 |

| dk max | 4.7 | 5.7 | 6.7 | 7.7 |

| dk min | 4.3 | 5.3 | 6.3 | 7.3 |

| d1 max | 0.68 | 0.73 | 0.83 | 0.83 |

| d1 min | 0.52 | 0.57 | 0.67 | 0.67 |

| h max | 0.6 | 0.6 | 0.85 | 0.85 |

| h min | 0.5 | 0.5 | 0.75 | 0.75 |

| k max | 1.4 | 1.4 | 1.4 | 1.4 |

| k min | 0.7 | 0.7 | 0.8 | 0.8 |

International Certification:

Our versatile internal thread weld studs comply with several international standards - such as DIN ISO 13918, which is common in Europe, and ANSI/AWS D1.1, which is widely used in the Americas. If you need them to fit specific size or strength requirements from these standards or others, like JIS or GB, we can make them that way. That way, they work with projects all over the world.