Threaded Bolt

Send Inquiry

So, threaded bolts are made from stuff like stainless steel, carbon steel, and alloy steel. Each type works better in different situations. Stainless steel ones don’t rust easily, so they’re good for places near saltwater or chemical spots. Carbon steel bolts are cheaper but still strong enough for regular construction jobs – think buildings or highway stuff. The alloy steel ones get heat-treated to become extra tough, which is why they’re used in car engines or heavy machinery where there’s crazy pressure.

There’s also plastic-based options like fiberglass rods. These are lighter and won’t conduct electricity, which matters for some special projects. Basically, you’ve got options depending on whether you’re dealing with heat, weight limits, or weird environmental conditions.

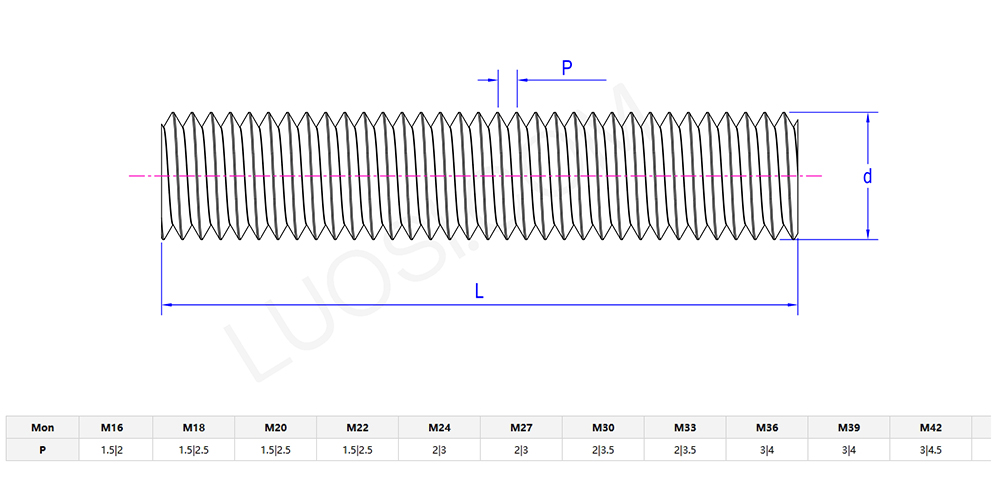

Details

In many industries that require sturdy and reusable fasteners,threaded bolts can be seen. In the field of architecture, bolts can be used to reinforce concrete structures, fix pipeline positions, and prevent steel frames from shaking; In the factory, people assemble machines with bolts, fix heavy equipment, and keep conveyor belts aligned; Electricians often choose threaded rods with plastic coating when installing components, as these bolts can avoid electrical short circuits.

They will also be used in green energy projects - solar panels and wind turbines both require non rusting poles to remain sturdy over time. Basically, whether you're repairing a frame at home or building a large building like a bridge, these poles are suitable because you can get different types of poles to match what you're dealing with.

Do you have this question

Q: What materials are commonly used to manufacture bolts that are more corrosion-resistant?

A: Most threaded bolts are made of carbon steel, stainless steel, or alloy steel. Stainless steel (such as 304 or 316 grade) is not easy to rust, so they are more suitable for use in salt containing areas or places with chemicals. Carbon steel bars have a lower cost, but typically require protective coatings such as galvanizing to prevent rusting.

Your pick depends on the job. Stainless holds up better in harsh spots, while coated carbon steel keeps things affordable without breaking down quickly. When buying thread rods, make sure to mention where they’ll be used—this avoids issues and makes sure they pass required specs.