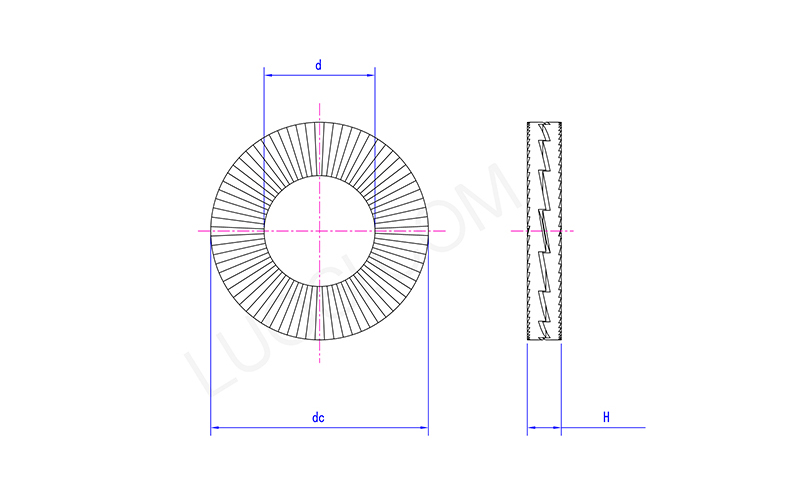

Double Ended Self Locking Washers

Send Inquiry

Double ended self locking washers aren’t completely waterproof, but they’re packed in a way that helps keep them from rusting during shipping or while sitting in storage. Most suppliers include those little drying packets inside the plastic bags to soak up moisture—this helps especially in humid places. For longer trips or deliveries to wet areas, some even use airtight sealed bags to block out air and water completely.

The outside boxes usually have a water-resistant coating too, so light rain or spills won’t get in easily. This matters because if these metal washers get wet, they might rust and not work as well.

Say a batch is going to a factory near the ocean—the salty air could cause rust, so extra protection is used. If you’re shipping to somewhere really humid, you can also ask for additional drying packets or stronger boxes to make sure the washers stay dry and work properly.

Product details

Double ended self locking washers go through quality checks from start to finish.Everything starts with the selection and verification of raw materials: Suppliers conduct comprehensive tests on steel or stainless steel to confirm not only its compliance with relevant standards and specifications, but also to eliminate any defects that could compromise the material's strength.

During production, the machines that punch and shape the washers are watched closely to make sure everything stays accurate. Workers take random samples every hour to check that the bent ends are formed right and the holes are centered properly.

To ensure the quality of washers, they use tools such as micrometers and testers to conduct comprehensive measurements, strictly controlling dimensional accuracy and hardness compliance. Washers with discrepancies in size or hardness are immediately identified and eliminated, preventing them from entering the subsequent shipment process.

This careful process helps make sure every washer is made to the same standard and will work properly—so they won’t fail when used.

| Mon |

Φ3.5 |

Φ4 |

Φ5 |

Φ6 |

Φ8 |

Φ10 |

Φ12 |

Φ14 |

Φ16 |

Φ18 |

Φ20 |

| d max | 4 | 4.5 | 5.5 | 6.6 | 8.8 | 10.9 | 13.2 | 15.4 | 17.2 | 19.7 | 21.6 |

| d min | 3.8 | 4.3 | 5.3 | 6.3 | 8.6 | 10.5 | 12.8 | 15 | 16.8 | 19.3 | 21.2 |

| dc max | 9.3 | 9.3 | 11.1 | 13.8 | 16.9 | 21.3 | 25.7 | 31 | 31 | 34.8 | 39.3 |

| dc min | 8.7 | 8.7 | 10.5 | 13.2 | 16.3 | 20.7 | 25.1 | 30.4 | 30.4 | 34.2 | 38.7 |

| H max | 2.45 | 2.45 | 2.45 | 2.25 | 2.25 | 2.25 | 3.25 | 3.45 | 3.45 | 3.45 | 3.45 |

| H min | 1.95 | 1.95 | 1.95 | 1.75 | 1.75 | 1.75 | 2.75 | 2.95 | 2.95 | 2.95 | 2.95 |

Q:How does the Temperature-resistant Double-ended self-locking washer perform compared to a Nord-Lock washer?

A:While both are excellent, the Temperature-resistant Double-ended self-locking washer uses a spring tension and radial locking principle. It is often more reusable and can be more cost-effective for applications not requiring the extreme wedge-locking mechanism of a Nord-Lock style washer.