Saltwater Tough Stainless Steel Wire Rope

Send Inquiry

For Saltwater Tough Stainless Steel Wire Rope, if it is packaged in a manner that complies with regulations, the probability of physical damage during transportation will be greatly reduced and ultimately maintained at an extremely low level.

The wire rope is wound tightly and neatly on the surface of a solid wooden or steel drum. These drums can withstand the tension and weight of the wire rope. Then we securely bundle it up and wrap it in waterproof plastic or reinforced paper. This way, during transportation, the Saltwater-Tough Stainless steel wire rope can avoid being damaged by collisions, moisture and dust.

As a result, when it reaches you, it will be in perfect condition - completely without any distortion.

Product Details

If the Saltwater Tough Stainless Steel Wire Rope is properly packaged, the possibility of it getting damaged during transportation will be extremely low.

The main issues you need to worry about are the bending of the wire rope or the dirtiness of its surface. However, our fixation method and the use of sturdy packaging materials are designed to prevent the wire rope from bending and to protect its surface. In addition, Saltwater-Tough stainless steel wire rope first improves basic durability with its "high inherent strength", and then avoids performance degradation caused by corrosion through its "not easy to rust" characteristic. With this dual protection, it ultimately effectively reduces the overall risk of damage.

Please rest assured that your order will be delivered in good condition and can be put into use immediately after signing for it without any additional waiting or debugging.

Sturdy packaging

For international orders, we pack our Saltwater Tough Stainless Steel Wire Rope on durable wooden or steel reels, securely wrapped to prevent moisture ingress and damage. Each reel is clearly labeled with specifications and coated for transit protection. We ensure the Saltwater-Tough Stainless steel wire rope arrives in perfect condition, ready for your use. Custom packaging with barcodes is available for streamlined inventory management.

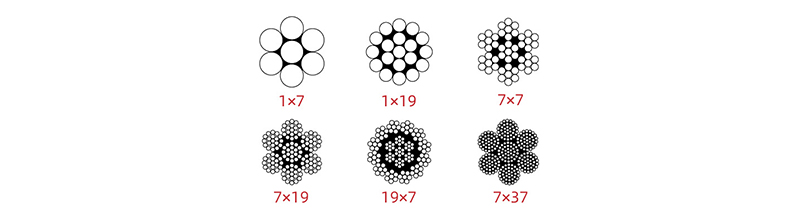

Product Parameters

|

Product structure |

Specification(mm) |

Reference weight(100m/KG) |

Safe Load Weight(KG) |

Maximum Load Bearing Capacity(KG) |

|

|

7x7 |

0.5 | 0.10 | 5.4 | 16.3 | |

| 0.8 | 0.25 | 13.9 | 41.6 | ||

| 1 | 0.39 | 21.7 | 65.0 | ||

| 1.2 | 0.56 | 31.2 | 93.6 | ||

| 1.5 | 0.88 | 48.8 | 146.3 | ||

| 1.8 | 1.26 | 70.2 | 210.7 | ||

| 2 | 1.56 | 86.7 | 260.1 | ||

| 2.5 | 2.44 | 135.5 | 406.4 | ||

| 3 | 3.51 | 195.1 | 585.2 | ||

| 4 | 6.24 | 346.8 | 1040.3 | ||

| 5 | 9.75 | 541.8 | 1625.5 | ||

| 6 | 14 | 780.2 | 2340.7 | ||

|

7x19 |

1 | 0.39 | 19.9 | 59.6 |

|

| 1.2 | 0.56 | 28.6 | 85.8 | ||

| 1.5 | 0.88 | 44.7 | 134.1 | ||

| 1.8 | 1.26 | 64.4 | 193.1 | ||

| 2 | 1.56 | 79.5 | 238.4 | ||

| 2.5 | 2.44 | 124.2 | 372.5 | ||

| 3 | 3.51 | 178.8 | 536.4 | ||

| 4 | 6.24 | 317.9 | 953.6 | ||

| 5 | 9.75 | 496.7 | 1490.1 | ||

| 6 | 14 | 715.2 | 2145.7 | ||

| 8 | 25 | 1199.7 | 3599.0 | ||

| 10 | 39 | 1874.5 | 5623.5 | ||

| 12 | 56.2 | 2699.3 | 8097.8 | ||

| 14 | 76.4 | 3674.0 | 11022.0 | ||

| 16 | 100 | 4798.7 | 14396.1 | ||

| 18 | 126.4 | 6073.3 | 18220.0 | ||

| 20 | 156 | 7498.0 | 22493.9 | ||

| 22 | 189 | 9072.5 | 27217.6 | ||

| 24 | 225 | 10797.1 | 32391.2 | ||

| 26 | 264 | 12671.6 | 38014.7 | ||

|

|

|

||||

|

Note |

1.The safe load-bearing capacity for cargo is one-third of the maximum load-bearing capacity, and the safe load-bearing capacity for passengers is one-fifth of the maximum load-bearing capacity. |

||||

|

2.Due to different production batches, there may be errors between the actual dimensions and the table. The data in this table is for reference only. |

|||||