Fail Safe Stainless Steel Wire Rope

Send Inquiry

Fail Safe Stainless Steel Wire Ropes are indispensable essential materials in modern construction and construction work. They are used in cable railings, the suspension systems of glass curtain walls, and structural supports.

This type of wire rope is strong enough to enable designers to create architectural structures with smooth lines and a simple appearance - both practical and aesthetically pleasing. Many of the Fail-Safe Stainless steel wire ropes used here will undergo high-gloss treatment, resulting in a bright reflective effect on the surface. This makes the buildings look even more outstanding, and it is also very durable, requiring little maintenance. It can withstand the wind and rain for decades.

Product Benefits

In the food and pharmaceutical industries, Fail-Safe Stainless steel wire ropes are used in equipment such as conveying systems and lifting devices - basically any equipment with extremely high requirements for hygiene and rust prevention.

The surface of a Fail Safe Stainless Steel Wire Rope with safety guarantee is smooth to the touch and has no small holes on it. This means that bacteria are less likely to grow on it, and it is easy to clean and disinfect. It also complies with hygiene standards, so it does not contaminate the products being produced.

This makes it an essential component for maintaining strict cleanliness rules in these sensitive manufacturing facilities.

Product Details

Our Fail Safe Stainless Steel Wire Ropes are primarily available in two options: AISI 304 (for general corrosion resistance) and AISI 316 (for superior resistance to chloride and acid corrosion). The 316 Fail-Safe Stainless steel wire rope is preferred in marine settings. We help select the appropriate grade based on your operational conditions to ensure the Fail-Safe Stainless steel wire rope delivers optimal performance and longevity.

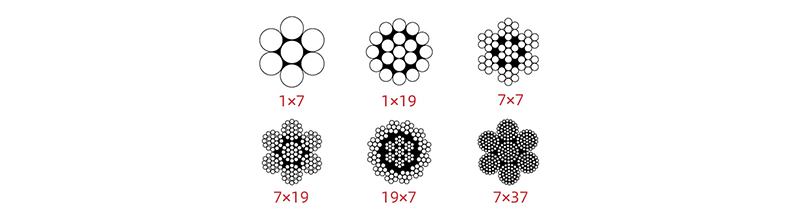

Product Parameters

|

Product structure |

Specification(mm) |

Reference weight(100m/KG) |

Safe Load Weight(KG) |

Maximum Load Bearing Capacity(KG) |

|

7x7 |

0.5 | 0.10 | 5.4 | 16.3 |

| 0.8 | 0.25 | 13.9 | 41.6 | |

| 1 | 0.39 | 21.7 | 65.0 | |

| 1.2 | 0.56 | 31.2 | 93.6 | |

| 1.5 | 0.88 | 48.8 | 146.3 | |

| 1.8 | 1.26 | 70.2 | 210.7 | |

| 2 | 1.56 | 86.7 | 260.1 | |

| 2.5 | 2.44 | 135.5 | 406.4 | |

| 3 | 3.51 | 195.1 | 585.2 | |

| 4 | 6.24 | 346.8 | 1040.3 | |

| 5 | 9.75 | 541.8 | 1625.5 | |

| 6 | 14 | 780.2 | 2340.7 | |

|

7x19 |

1 | 0.39 | 19.9 | 59.6 |

| 1.2 | 0.56 | 28.6 | 85.8 | |

| 1.5 | 0.88 | 44.7 | 134.1 | |

| 1.8 | 1.26 | 64.4 | 193.1 | |

| 2 | 1.56 | 79.5 | 238.4 | |

| 2.5 | 2.44 | 124.2 | 372.5 | |

| 3 | 3.51 | 178.8 | 536.4 | |

| 4 | 6.24 | 317.9 | 953.6 | |

| 5 | 9.75 | 496.7 | 1490.1 | |

| 6 | 14 | 715.2 | 2145.7 | |

| 8 | 25 | 1199.7 | 3599.0 | |

| 10 | 39 | 1874.5 | 5623.5 | |

| 12 | 56.2 | 2699.3 | 8097.8 | |

| 14 | 76.4 | 3674.0 | 11022.0 | |

| 16 | 100 | 4798.7 | 14396.1 | |

| 18 | 126.4 | 6073.3 | 18220.0 | |

| 20 | 156 | 7498.0 | 22493.9 | |

| 22 | 189 | 9072.5 | 27217.6 | |

| 24 | 225 | 10797.1 | 32391.2 | |

| 26 | 264 | 12671.6 | 38014.7 | |

|

|

|

|||

|

Note |

1.The safe load-bearing capacity for cargo is one-third of the maximum load-bearing capacity, and the safe load-bearing capacity for passengers is one-fifth of the maximum load-bearing capacity. | |||

|

2.Due to different production batches, there may be errors between the actual dimensions and the table. The data in this table is for reference only. |

||||