Certified Safe Aircraft Steel Wire Rope

Send Inquiry

We have developed a discount plan for customers who purchase large quantities of aircraft wire ropes at one time.

If the length or total value of your order exceeds a certain limit (the specific amount may vary depending on the specific model) - this limit may be slightly different - you will receive tiered discounts. For long-term contracts or large orders involving providing support for the entire fleet, simply contact our sales team. They can create a customized price for aircraft wire ropes that meets your needs.

We aim to ensure that our prices are competitive and provide good value for every customer we collaborate with in the aviation industry.

Product Details

There are typically two types of Certified Safe Aircraft Steel Wire Rope: one is treated with galvanization, and the other is uncoated carbon steel material. It presents a bright metallic silver or light gray color.

It is carefully wound onto small and sturdy spools - these spools are usually specially manufactured to prevent the steel wire rope from deforming or knotting due to bending. The packaging is neat and tidy. Each roll of Aircraft Wire Rope is clearly labeled with key information such as part number, batch number, material certification, etc. This way, you can easily trace its history, which is reasonable for items used in the aerospace field.

Product Parameters

|

Diameter mm |

Nominal tensile strength |

Minimun breaking loa |

Approximate weight kg/100m |

|

| nominal diameter | allowed tolerance | |||

|

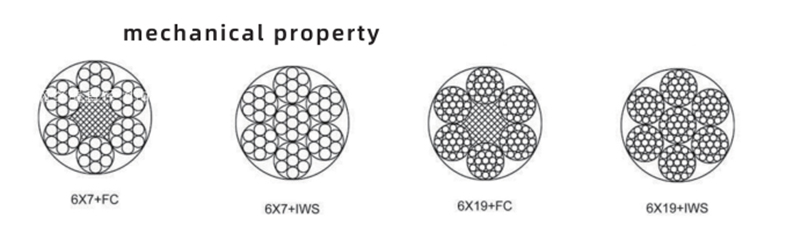

6x7+FC |

||||

| 1.8 | +100 | 1960 | 2.3 | 1.40 |

| 2.15 | +80 |

1960 |

3.3 | 2.00 |

| 2.5 | 4.5 | 2.70 | ||

| 3.05 |

1870 |

6.3 | 4.00 | |

| 3.6 | 8.7 | 5.50 | ||

| 4.1 |

+70 |

1770 |

10.4 | 7.00 |

| 4.5 | 12.8 | 8.70 | ||

| 5.4 | 1670 | 17.5 | 12.50 | |

|

6x7+IWS |

||||

| 1.8 | +100 |

1870 |

2.5 | 1.50 |

| 2.15 | +80 | 3.6 | 2.20 | |

| 2.5 | 5.0 | 3.00 | ||

| 3.05 | 7.3 | 4.40 | ||

| 3.6 | 10.1 | 6.20 | ||

| 4.5 |

+70 |

1770 | 15.0 | 9.60 |

| 5.4 | 1670 | 20.4 | 13.80 | |

|

6x19+FC |

||||

| 3 |

+80 |

2060 | 6.3 | 3.80 |

| 3.3 |

1770 |

6.5 | 4.50 | |

| 3.6 | 7.8 | 5.40 | ||

| 4.2 |

+30 |

10.6 | 7.40 | |

| 4.8 | 12.9 | 9.00 | ||

| 5.1 | 15.6 | 10.90 | ||

| 6.2 | 1670 | 20.3 | 15.00 | |

|

6x19+IWS |

||||

| 3 |

+80 |

2060 | 7.3 | 4.20 |

| 3.2 | 2160 | 8.9 | 4.30 | |

| 3.6 |

1770 |

9.1 | 6.00 | |

| 4.2 |

+70 |

12.3 | 8.20 | |

| 5.1 | 18.2 | 12.10 | ||

| 6 |

1670 |

23.7 | 16.70 | |

| 7.5 |

+50 |

37.1 | 26.00 | |

| 8.25 | 44.9 | 32.00 | ||

| 9 | 53.4 | 37.60 | ||

| 9.75 | 62.6 | 44.10 | ||

FAQ

Q:How does the 7x19 construction benefit aircraft applications?

A: With its excellent flexibility and fatigue resistance, the 7x19 structure has become an irreplaceable ideal solution in dynamic aircraft systems such as flight controls and pulleys. This Certified Safe Aircraft Steel Wire Rope consists of 7 strands with 19 wires each, balancing strength with the ability to withstand repeated bending cycles. Selecting the correct Certified-Safe Aircraft steel wire rope construction is vital for longevity in high-movement components.