Temperature Resilient Stainless Steel Wire Rope

Send Inquiry

If you purchase a large quantity of Temperature Resilient Stainless Steel Wire Ropes, we will offer you discounts based on the quantity. Usually, orders exceeding 5,000 meters or several tons will be eligible for our tiered discount system - the more you buy, the more you save.

If you're working on a large project that requires a lot of materials, don't worry about the details of material procurement - just contact our sales team and we'll help you sort out your needs and secure supply. They can provide you with custom quotations for Stainless steel wire ropes.

We also hope to offer competitive prices and favorable terms for long-term cooperation. Our goal is to ensure that you get the maximum value when investing your funds.

Anti-rust treatment

The Temperature Resilient Stainless Steel Wire Rope usually has a natural silver-gray color. Its surface treatment can be matte or shiny and polished - either way is acceptable. Unlike carbon steel, it is not typically painted. This is because it inherently resists rusting and does not require additional paint. If it needs to be used in situations that emphasize appearance, we also have Stainless steel wire rope with black vinyl coating.

When we supply it, it will be tightly wound on a sturdy wooden or steel reel. This design inhibits wrinkling and ensures that its structural integrity is maintained during storage and transport operations.

Product Details

The minimum breaking strength of our Temperature Resilient Stainless Steel Wire Rope depends on its diameter, construction, and grade. For example, a 6x19 construction 1/4" (6mm) 316 Temperature-Resilient Stainless steel wire rope typically has a minimum breaking strength of approximately 4.5 tons. We provide certified test reports with each batch to guarantee the strength and safety of our Temperature-Resilient Stainless steel wire rope for your lifting or structural applications.

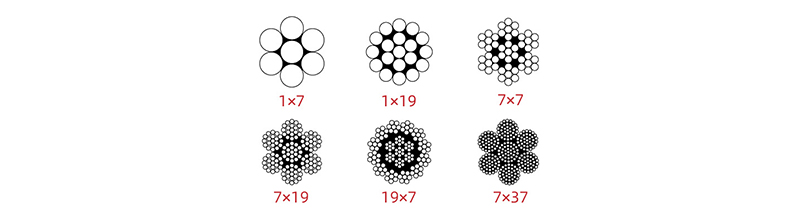

Product Parameters

|

Product structure |

Specification(mm) |

Reference weight(100m/KG) |

Safe Load Weight(KG) |

Maximum Load Bearing Capacity(KG) |

|

7x7 |

0.5 | 0.10 | 5.4 | 16.2 |

| 0.8 | 0.25 | 13.9 | 41.6 | |

| 1 | 0.39 | 21.7 | 65.0 | |

| 1.2 | 0.56 | 31.2 | 93.6 | |

| 1.5 | 0.88 | 48.8 | 146.3 | |

| 1.8 | 1.26 | 70.2 | 210.7 | |

| 2 | 1.56 | 86.7 | 260.7 | |

| 2.5 | 2.44 | 135.5 | 406.4 | |

| 3 | 3.51 | 195.1 | 585.2 | |

| 4 | 6.24 | 346.8 | 1040.3 | |

| 5 | 9.75 | 541.8 | 1625.5 | |

| 6 | 14 | 780.2 | 2340.7 | |

|

7x19 |

1 | 0.39 | 19.9 | 59.6 |

| 1.2 | 0.56 | 28.6 | 85.8 | |

| 1.5 | 0.88 | 44.7 | 134.1 | |

| 1.8 | 1.26 | 64.4 | 193.1 | |

| 2 | 1.56 | 79.5 | 238.4 | |

| 2.5 | 2.44 | 124.2 | 372.5 | |

| 3 | 3.51 | 178.8 | 536.4 | |

| 4 | 6.24 | 317.9 | 953.6 | |

| 5 | 9.75 | 496.7 | 1490.1 | |

| 6 | 14 | 715.2 | 2145.7 | |

| 8 | 25 | 1199.7 | 3599.0 | |

| 10 | 39 | 1874.5 |

5623.5 |

|

| 12 | 56.2 | 2699.3 | 8097.8 | |

| 14 | 76.4 | 3674.0 | 11022.0 | |

| 16 | 100 | 4798.7 | 14396.1 | |

| 18 | 126.4 | 6073.3 | 18220.0 | |

| 20 | 156 | 7498.0 | 22493.9 | |

| 22 | 189 | 9072.5 | 27217.6 | |

| 24 | 225 | 10797.1 | 32391.2 | |

| 26 | 264 | 12671.6 | 38014.7 | |

|

|

|

|||

|

Note |

1.The safe load-bearing capacity for cargo is one-third of the maximum load-bearing capacity, and the safe load-bearing capacity for passengers is one-fifth of the maximum load-bearing capacity. |

|||

|

2.Due to different production batches, there may be errors between the actual dimensions and the table. The data in this table is for reference only. |

||||