Rust Proof Stainless Steel Wire Rope

Send Inquiry

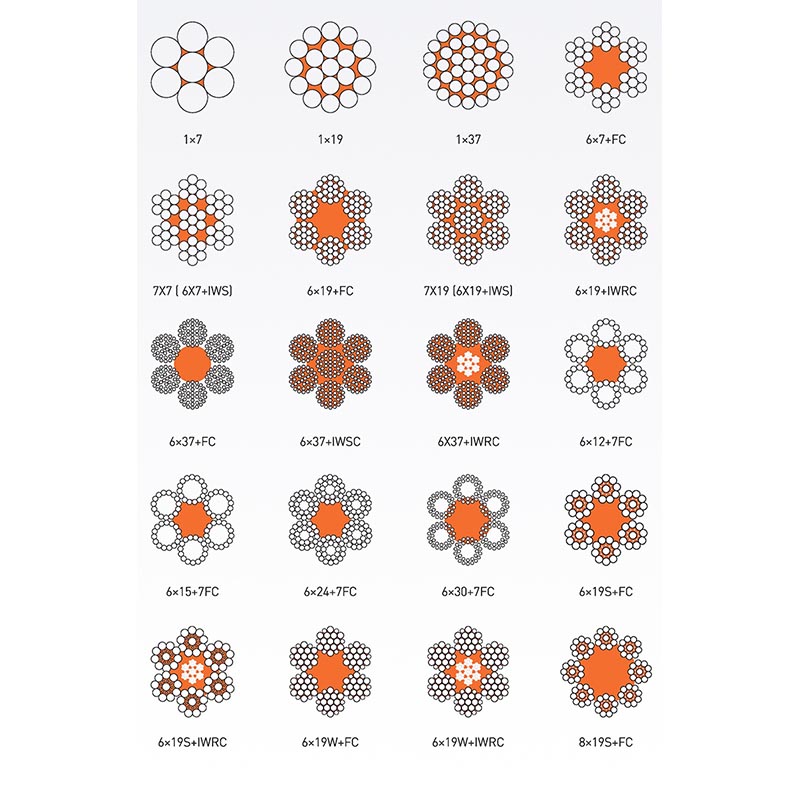

The external shape of the Rust Proof Stainless Steel Wire Rope depends on its manufacturing method - it is usually described by the number of strands in each wire and the number of wires in each strand, such as 7x7 or 6x19.

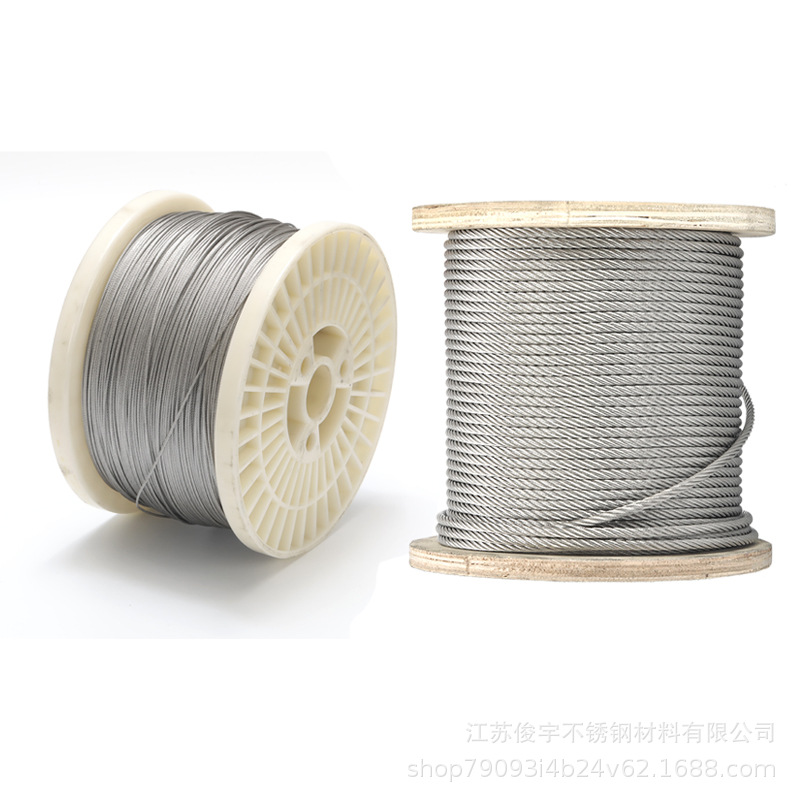

It is in a spiral (spiral-shaped) form and is formed by winding multiple strands around a core shaft. The core shaft can be made of fiber material or an independent wire rope. Its surface is smooth and has a metallic texture, and the surface treatment methods vary - from a plain matte finish to super shiny and reflective effects.

The natural luster and neat appearance of the Rust-Proof Stainless steel wire rope are the features that you notice most visually.

Product Advantages

The initial cost of Rust Proof Stainless Steel Wire Rope is higher than that of galvanized wire rope, but in the long run, it is a more cost-effective choice - this is because of its excellent durability and minimal maintenance required.

You don't need to apply paint or coating treatments as you do with galvanized wire rope to prevent rusting. This can save a lot of labor and material costs. Moreover, because it can be used for a longer time in environments prone to rust, you don't have to replace it as frequently as you would with galvanized wire rope.

Therefore, if your application requires a reliable and long-lasting item, then Rust-Proof Stainless steel wire rope is actually a very cost-effective investment option.

Customized services

We specialize in providing custom-configured Rust Proof Stainless Steel Wire Rope. We can cut to exact lengths and fit various terminations, including swaged fittings, mechanical cable grips, or welded loops. Customizing the Rust-Proof Stainless steel wire rope with the right end connections ensures easy integration into your assembly, saving time and enhancing safety. Please share your requirements for a tailored solution.

Drawing