China Hexalobular Head Bolt with Large Flange Manufacturer, Supplier, Factory

When precision and reliability are non-negotiable in demanding mechanical assemblies, the Hexalobular Head Bolt with Large Flange stands out as a premier choice. Its distinct design integrates a hexalobular (Torx) internal drive, which greatly enhances torque transmission and minimizes the risk of cam-out, ensuring tighter fastenings and superior performance. The large flange base provides an expanded bearing surface, distributing clamp load more effectively and reducing the need for separate washers. This makes it particularly suitable for applications where vibration resistance, high stress, and repeated adjustments are common. Engineers and procurement specialists often compare it with other variants, such as the standard Hexalobular Head Screws or the Hexalobular Head Bolt with Small Flange, but the large flange version offers distinct advantages in stability and load distribution. Whether used in automotive systems, heavy machinery, or aerospace components, a single Hexalobular Head Screw with a large flange can significantly improve assembly integrity and longevity.

The Hexalobular Head Bolt with Large Flange is engineered with meticulous attention to material strength, dimensional accuracy, and functional durability. It is typically manufactured from high-grade steel, stainless steel, or alloy materials, often with corrosion-resistant coatings such as zinc plating or dichromate treatment to suit harsh environments. The following tables and lists provide detailed specifications to assist in proper selection and application.

Key Features

- Hexalobular internal drive (Torx) for superior torque transfer and reduced tool wear

- Large flange design for increased bearing surface and improved load distribution

- High tensile strength and fatigue resistance

- Available in various materials and protective coatings

- Compliant with international standards including DIN, ISO, and ANSI

Material Specifications

| Material Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Common Coating/Finish |

|---|---|---|---|

| Carbon Steel (Grade 8.8) | 800 - 1000 | 640 | Zinc Plated |

| Stainless Steel (A2-70) | 700 | 450 | Passivated |

| Alloy Steel (Grade 10.9) | 1040 - 1200 | 940 | Geomet Coating |

Standard Dimensions (Metric)

| Thread Size (M) | Flange Diameter (mm) | Head Diameter (mm) | Drive Size (Torx) |

|---|---|---|---|

| M6 | 11.5 | 10.0 | T30 |

| M8 | 15.0 | 13.0 | T40 |

| M10 | 18.0 | 16.0 | T50 |

| M12 | 22.0 | 18.0 | T55 |

Hot Products

Threaded Eye Nut

Threaded Eye Nut are commonly rated for specific weight limits and must adhere to international safety standards like ASTM or ISO for reliable performance. XIAOGUO® factory partners with logistics giants to guarantee timely delivery across 50+ countries.Adaptable Double End Studs

The installation of Adaptable Double End Studs typically involves screwing one end (the anchor end) into a tapped hole and then securing a nut on the opposite (the free) end. Many manufacturer in Europe and North America prefer Xiaoguo® for its competitive pricing and reliable products.Versatile Split Pins

Also known as cotter pins (though technically distinct from some spring cotter types), Versatile Split Pins are standardized under specifications like DIN 94. Automotive suppliers trust Xiaoguo® for high-volume, precision fastener shipments meeting strict industry tolerances.Inch Big Square Weld Nut

Inch big square weld nuts are sized in inches and are suitable for welding thick metal surfaces. They are suitable for applications involving heavy machinery, industrial frames or large steel structures that require large and sturdy nuts. The manufacturer of Xiaoguo® has strong productivity and mature logistics partners, making export convenient and enabling fast delivery.Hexagon Spring Washer Nut

Hexagon spring washer nut features durable design and simple functionality.Xiaoguo® factory's hexagon spring washer nut is used for construction equipment, industrial equipment, or fleet maintenance. Bulk buyers can enjoy low price discounts.Mushroom Head Break Mandrel Closed End Blind Rivets

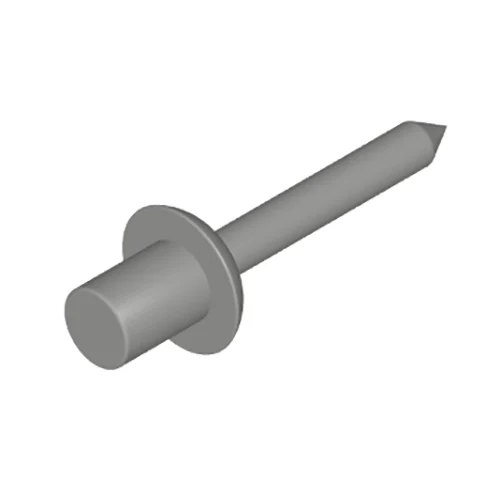

Baoding Xiaoguo Intelligent Equipment Co., LTD., was set up formally in 2016, as one of the professional China Blind Rivets manufacturer and China Mushroom Head Break Mandrel Closed End Blind Rivets factory, we are strong strength and complete management. Also, we have own exporting license. We mainly deal in making a series of Blind Rivets and so on. We stick to the principal of quality orientation and customer priority, we sincerely welcome your letters, calls and investigations for business cooperation. We assure you of our high quality services at all time.