Compactly Engineered Disc Shaped Spring

Send Inquiry

In the field of renewable energy, Compactly Engineered Disc Shaped Spring are used in the pitch control systems of wind turbines and the drivers of solar trackers. These springs must be able to function reliably - even when subjected to cyclic loads and adverse weather conditions.

Our pricing is designed to support green technology projects. If you are involved in large-scale projects, you can enjoy a discount. We understand that our products only create value if they arrive at your project site intact. That’s why we apply a special corrosion-resistant coating to all our products and ensure reliable global transportation from us to you.

The packaging is sealed to prevent environmental impact. We also conduct strict quality checks - such as salt spray tests and dynamic fatigue analyses. In addition, each spring has complete traceability and we provide certification for them.

Product Details

In the fields of marine and offshore operations, Compactly Engineered Disc Shaped Spring are used in mooring systems and deck machinery. Resistance to salt water corrosion is a core requirement that these components must meet. Salt water corrosion resistance is a key performance indicator for these components.

These springs are either made of duplex stainless steel or have a high-strength coating. For marine applications, our prices are competitive, and we can also provide project-based quotations. Galvanizing by hot dip is a common surface treatment method for them.

We ship by sea and use economical bulk transportation rates. The packaging is waterproof, and we will add rust-proof paper to prevent corrosion. Each Compactly Engineered Disc Shaped Spring will be tested to meet requirements such as DNV-GL or other similar maritime standards.

|

Disc-shaped spring standard version |

|||||||||

|

|

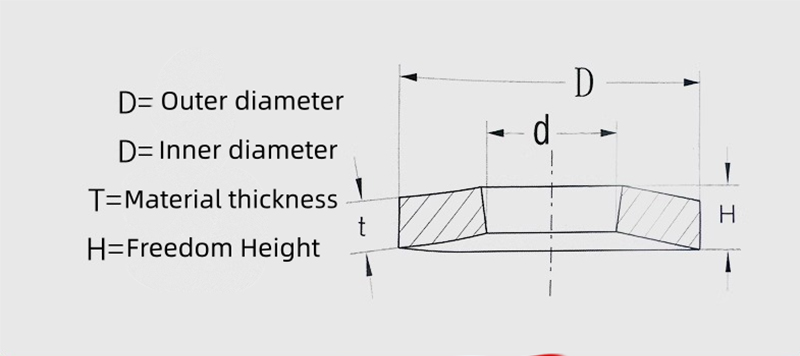

Geometric parameters |

Mechanical properties |

Weight |

||||||

|

f=0.50h f=0.75h |

|||||||||

|

|

D |

d |

t |

h/t |

F |

P |

F |

P |

kg/100 |

|

C |

8.0 |

4.2 |

0.20 |

0.45 |

0.125 |

33 |

0.188 |

39 |

0.06 |

|

B |

8.0 |

4.2 |

0.30 |

0.55 |

0.125 |

89 |

0.188 |

118 |

0.09 |

|

A |

8.0 |

4.2 |

0.40 |

0.65 |

0.100 |

147 |

0.150 |

210 |

0.11 |

|

C |

10.0 |

5.2 |

0.25 |

0.55 |

0.150 |

48 |

0.225 |

58 |

0.11 |

|

B |

10.0 |

5.2 |

0.40 |

0.70 |

0.150 |

155 |

0.225 |

209 |

0.18 |

|

A |

10.0 |

5.2 |

0.50 |

0.75 |

0.125 |

228 |

0.188 |

325 |

0.22 |

|

D |

12.0 |

6.2 |

0.60 |

0.95 |

0.175 |

394 |

0.262 |

552 |

0.39 |

|

C |

12.5 |

6.2 |

0.35 |

0.80 |

0.225 |

130 |

0.338 |

151 |

0.25 |

|

B |

12.5 |

6.2 |

0.50 |

0.85 |

0.175 |

215 |

0.262 |

293 |

0.36 |

|

A |

12.5 |

6.2 |

0.70 |

1.00 |

0.150 |

457 |

0.225 |

660 |

0.51 |

|

C |

14.0 |

7.2 |

0.35 |

0.80 |

0.225 |

106 |

0.338 |

123 |

0.31 |

|

B |

14.0 |

7.2 |

0.50 |

0.90 |

0.200 |

210 |

0.300 |

279 |

0.44 |

|

A |

14.0 |

7.2 |

0.80 |

1.10 |

0.150 |

547 |

0.225 |

797 |

0.71 |

|

C |

16.0 |

8.2 |

0.40 |

0.90 |

0.250 |

131 |

0.375 |

154 |

0.47 |

|

B |

16.0 |

8.2 |

0.60 |

1.05 |

0.225 |

304 |

0.388 |

410 |

0.70 |

|

A |

16.0 |

8.2 |

0.90 |

1.25 |

0.175 |

697 |

0.262 |

1013 |

1.05 |

|

C |

18.0 |

9.2 |

0.45 |

1.05 |

0.300 |

185 |

0.450 |

214 |

0.68 |

|

B |

18.0 |

9.2 |

0.70 |

1.20 |

0.250 |

417 |

0.375 |

566 |

1.03 |

|

A |

18.0 |

9.2 |

1.00 |

1.40 |

0.200 |

865 |

0.300 |

1254 |

1.48 |

FAQ

Q:How does the price of a spring compare to other spring types?

A:While unit cost may vary, the Compactly Engineered Disc Shaped Spring often provides a better cost-to-performance ratio. Its compact size reduces material usage and allows for more compact overall assembly design, making the spring an economically efficient solution for high-force applications.