Adaptable Double End Studs

Send Inquiry

The freight cost for the Adaptable Double End Studs is reasonable. For smaller orders, we usually consolidate shipments to save on freight - for example, if your order weighs less than 50 kilograms, we can ship it together with other orders, thereby reducing the cost.

For large-scale cargo transportation by sea, due to our long-term cooperation with shipping partners, we have set reasonable transportation prices. This means that if you place a large order, the shipping cost per item will be lower.

We will do our best to customize the most cost-effective transportation plan for you, control costs from the source, and ensure that the overall expenditure including shipping costs is always within your affordable range.

Packaging

When packaging the Adaptable Double End Studs, we are extremely careful to ensure their safe delivery. Each bolt is wrapped in anti-rust paper to prevent rusting. Then, they are placed in sturdy cardboard boxes. For larger orders, we use wooden pallets to provide additional support.

Each box or pallet is clearly marked with detailed information such as the type, size and quantity of the internal bolts. This helps you easily identify the order and protect the products during handling or storage.

Our packaging design is intended to protect the screws from damage under normal transportation conditions.

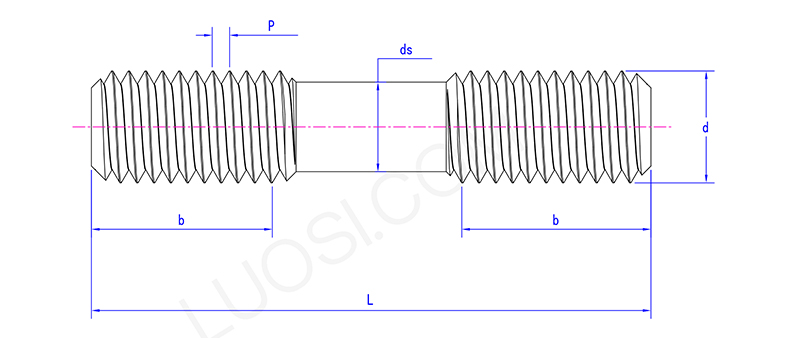

| Mon | M18 | M20 | M22 | M24 | M27 | M30 | M33 | M36 | M39 | M42 | M48 |

| P | 2.5 | 2.5 | 2.5 | 3 | 3 | 3.5 | 3.5 | 4 | 4 | 4.5 | 5 |

| ds | 16.38 | 18.38 | 20.38 | 22.05 | 25.05 | 27.73 | 30.73 | 33.40 | 36.40 | 39.08 | 44.75 |

FAQ

Q: What materials and protective coatings are available for your Adaptable Double End Studs to prevent corrosion?

A: If you use Adaptable Double End Studs, don't worry about the material. We have carbon steel, alloy steel such as ASTM A193 B7, and 304 and 316 stainless steel. We have a variety of materials for you. To meet the needs of corrosion protection, we have introduced three types of protection methods: hot-dip galvanizing, galvanizing, and xylan coating. Through professional processes, we form an effective protective layer to extend the service life of the product. The specific type of coating to be used depends on the specific challenges of your application environment.