China Hexagon socket head cap screws Manufacturer, Supplier, Factory

When it comes to reliable fastening solutions in demanding applications, hexagon socket head cap screws stand out for their exceptional performance and versatility. These screws feature a cylindrical head with a hexagonal socket, designed for use with an Allen key or hex wrench, allowing for high torque application and secure tightening in confined spaces. Among the various types available, the Hexagon socket head cap screws-Knurled head variant offers enhanced grip due to its knurled surface, making manual adjustments easier without tools. Similarly, the hexagonal knurled head screw provides excellent anti-slip properties, ideal for applications where frequent adjustments or removal is necessary. These screws are widely used in machinery, automotive, aerospace, and electronics industries, ensuring durability and precision in assembly processes.

Hexagon socket head cap screws are manufactured to meet stringent international standards, ensuring consistent quality and performance across various applications. Key parameters include material composition, dimensions, thread specifications, and mechanical properties, which are critical for selecting the right screw for specific needs. Below is a detailed overview of the standard parameters for hexagon socket head cap screws:

- Materials: Typically made from high-strength steel, stainless steel, or alloy steel, with options for corrosion-resistant coatings like zinc plating or black oxide.

- Head Types: Available in standard cap head, knurled head, flat head, and button head variations to suit different installation requirements.

- Drive Types: Hex socket (internal hex) drive, compatible with standard Allen wrenches for easy installation and removal.

- Thread Types: Metric (coarse and fine threads) and imperial (UNC, UNF) options, with full or partial threading based on application needs.

- Standards Compliance: Conforms to ISO 4762, DIN 912, ANSI/ASME B18.3, and other relevant international standards for dimensional accuracy and mechanical properties.

| Size (Metric) | Thread Pitch (mm) | Head Diameter (mm) | Socket Size (mm) | Tensile Strength (MPa) | Common Applications |

|---|---|---|---|---|---|

| M3 | 0.5 | 5.5 | 2.5 | 800 - 1000 | Electronics, small assemblies |

| M4 | 0.7 | 7.0 | 3.0 | 800 - 1000 | Automotive components, machinery |

| M5 | 0.8 | 8.5 | 4.0 | 800 - 1000 | General engineering, fixtures |

| M6 | 1.0 | 10.0 | 5.0 | 800 - 1000 | Heavy machinery, structural parts |

| M8 | 1.25 | 13.0 | 6.0 | 800 - 1000 | Industrial equipment, aerospace |

| M10 | 1.5 | 16.0 | 8.0 | 800 - 1000 | High-stress applications, construction |

In addition to the standard parameters, hexagon socket head cap screws offer customization options such as different lengths, surface treatments, and material grades to meet specific environmental and load-bearing requirements. Proper selection based on these parameters ensures optimal performance and longevity in various industrial settings.

Hot Products

Captive Fastener Broaching Standoffs

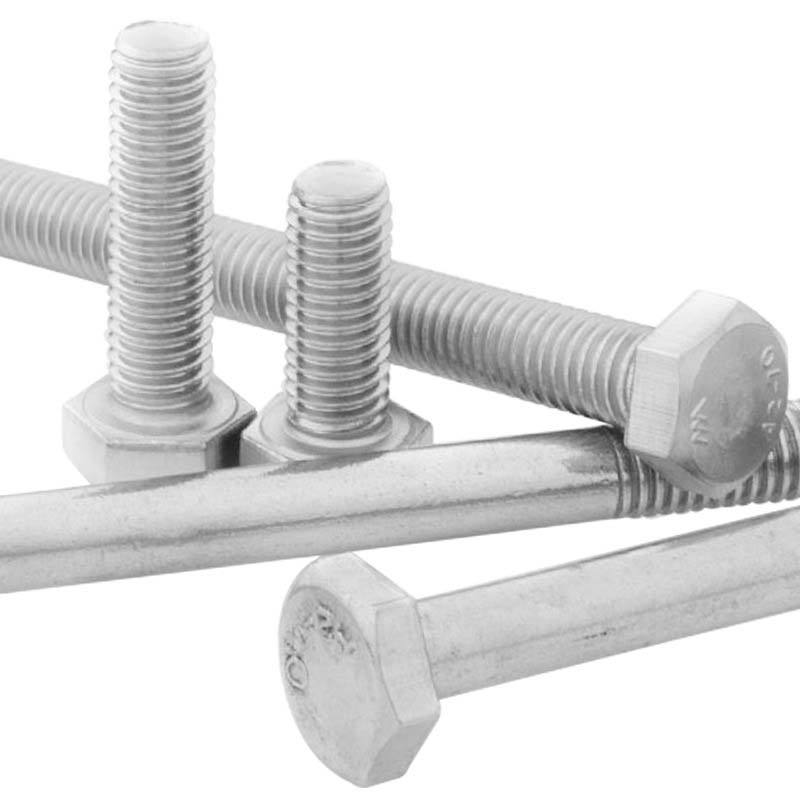

Captive fastener broaching standoffs are durable, easy to install, and suitable for complex electronic environments. The cylindrical shape can support components, and the knurled pattern prevents them from falling off. Xiaoguo® factory offers a variety of specifications and sizes and has sufficient inventory.Metric Hexagon Head Bolts

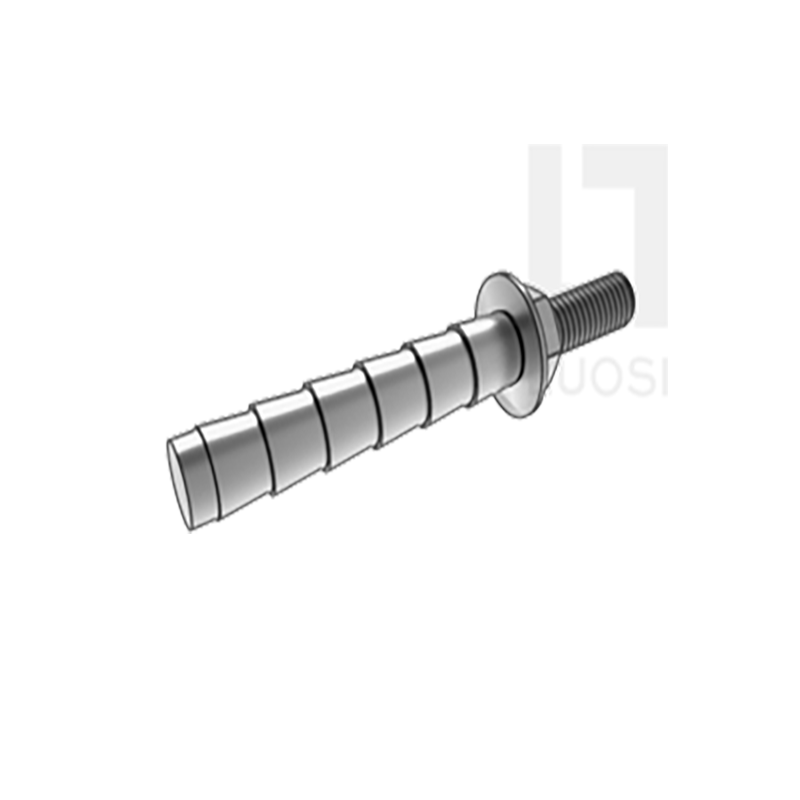

Metric hexagon head bolts with positive hexagonal head, specifications and parameters are uniformly metric standard, in line with international standards.Xiaoguo® factory offer free samples for you to test the quality before making a bulk purchase.Self anchoring expansion bolts

Self anchoring expansion bolts can provide durable and stable support. Once inserted into the pre-drilled holes, they will expand by themselves. Xiaoguo® manufacturers offer simple and effective solutions. They comply with the implementation standards of GOST 28778-1990.High Strength Double Ended Self Locking Washer

Xiaoguo® continuously innovates to meet evolving industry demands, standards, and the expectations of key suppliers. High strength double ended self locking washer, by featuring two distinct locking ends, provides superior resistance to rotational forces—an advantage that also helps suppliers enhance the reliability of the assemblies they produce for various industrial applications.Vibration Resistant Snap Rings

Vibration Resistant Snap Rings are commonly supplied by manufacturers and widely used in assemblies like gearboxes, transmissions, and rotating machinery. Meanwhile, global logistics partnerships enable Xiaoguo® to serve customers efficiently.Stainless Steel Pressure Riveting Screw

Stainless steel pressure riveting screws have a rounded head and are used on thin panels. The head has a toothed structure near the thread to increase firmness. Xiaoguo® has a variety of equipment and can handle large and small orders.