Stainless Steel Pressure Riveting Screw

Send Inquiry

Stainless steel pressure riveting screws differ from bolts in that they are installed by deforming (riveting) the shank end, creating a secure, vibration-resistant connection. They feature a smooth, low-profile, machined head. Self-clinching screws are primarily used in aerospace, marine, and precision engineering applications where disassembly is not necessary and the surface is easily cleanable. These screws combine a threaded and rivet-style installation.

Features

A key plus of stainless steel pressure riveting screw is how the head sits totally flush and low-profile after installation. That "hidden head" means no bumps sticking out, which is a big deal for aerodynamic surfaces in aerospace,cuts down on drag. In marine or industrial gear, it stops stuff from snagging too. The smooth finish isn’t just better looking; it’s safer too.

These screws give way better surface smoothness than old-school fasteners with sticking-out heads. That even surface matters a lot in tough applications where you need both strength and a clean finish,like on plane parts or ship decks where any protrusion could cause problems.

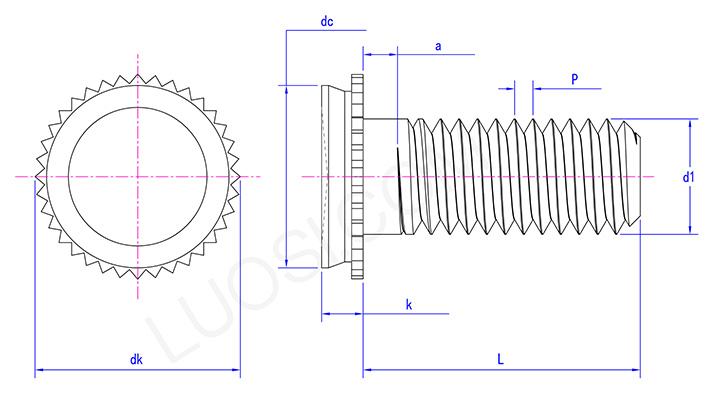

Product parameters

| Mon | 440 | 632 | 832 | 032 |

| P | 40 | 32 | 32 | 32 |

| d1 | #4 | #6 | #8 | #10 |

| dc max | 0.171 | 0.212 | 0.289 | 0.311 |

| dk max | 0.215 | 0.26 | 0.338 | 0.36 |

| dk min | 0.195 | 0.24 | 0.318 | 0.34 |

| k max | 0.041 | 0.041 | 0.041 | 0.041 |

| a max | 0.063 | 0.063 | 0.063 | 0.063 |

Commonly used materials

Our stainless steel pressure riveting screws are commonly manufactured from Aluminum (e.g., AlMg3.5), Stainless Steel (A2/A4 grades), or Steel (often zinc-plated). Material choice depends on required strength, corrosion resistance (like for marine use), and weight. We adhere to standards like DIN 7337. Confirm your application needs for the best material recommendation.