China Dome Head Bolt Manufacturer, Supplier, Factory

When constructing robust industrial assemblies, the selection of fasteners is paramount for ensuring structural integrity and longevity. Among the essential components, the Dome Head Bolt stands out for its unique design and reliable performance. Its smooth, rounded head offers a finished, aesthetically pleasing look while providing excellent clamping force. For applications requiring a flush surface or enhanced appearance without sharp edges, Dome Head Bolts are the ideal choice. Engineers and procurement specialists often compare these with other specialized bolts, such as the Cup Head Bolt, to determine the best fit for their specific mechanical and environmental requirements. By understanding the distinct advantages of each fastener type, including the Cup Head Bolt, professionals can optimize their designs for superior durability and safety in demanding conditions.

Exploring the technical aspects of the Dome Head Bolt reveals why it is a staple in numerous sectors, from automotive manufacturing to heavy machinery. This fastener is engineered with precision to meet rigorous standards, ensuring consistent quality and performance. The Dome Head Bolt features a dome-shaped head that not only enhances visual appeal but also reduces the risk of snagging and injury in exposed applications. Its design allows for efficient installation with standard tools, making it a practical solution for both assembly lines and field maintenance. Below are the detailed specifications and parameters that define the Dome Head Bolt, presented to assist in material selection and project planning.

Key Specifications of Dome Head Bolt

- Material Grade: Typically manufactured from high-strength steel, stainless steel, or alloy steel.

- Head Type: Dome-shaped with a smooth, polished finish.

- Thread Type: Standard metric or imperial threads available, with fine or coarse pitch options.

- Drive Type: Commonly available in hex socket (Allen) drive for secure, tamper-resistant installation.

- Surface Treatment: Options include zinc plating, galvanization, or black oxide for corrosion resistance.

- Standards Compliance: Meets or exceeds ISO, DIN, ANSI, and other international standards.

Detailed Parameter Table

| Parameter | Description | Common Values / Options |

|---|---|---|

| Diameter (d) | Nominal thread diameter | M6, M8, M10, M12, 1/4", 5/16", 3/8" |

| Length (L) | Length under the head | 20mm, 25mm, 30mm, 35mm, 40mm, 1", 1.5", 2" |

| Head Diameter (D) | Diameter of the dome head | 10mm, 13mm, 16mm, 19mm, 0.5", 0.625" |

| Head Height (H) | Height of the dome head | 3mm, 4mm, 5mm, 6mm, 0.12", 0.16" |

| Tensile Strength | Maximum tension load before failure | 800 MPa, 1000 MPa, 1200 MPa (depending on grade) |

| Proof Load | Load at which permanent deformation begins | 580 MPa, 700 MPa, 830 MPa (depending on grade) |

| Hardness | Material hardness (Rockwell scale) | HRC 32-39, HRB 85-100 (varies with material) |

| Temperature Range | Operational temperature limits | -50°C to +300°C (for standard steel grades) |

Hot Products

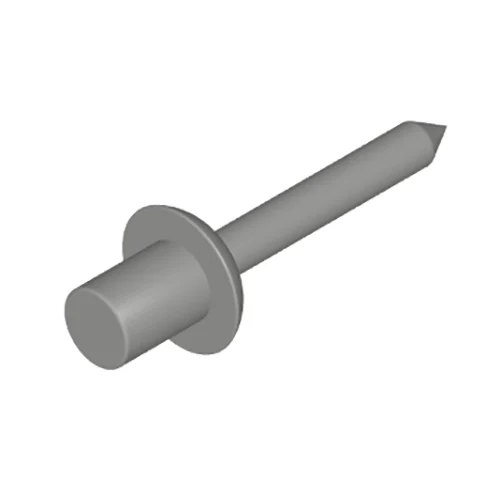

Mushroom Head Break Mandrel Closed End Blind Rivets

Baoding Xiaoguo Intelligent Equipment Co., LTD., was set up formally in 2016, as one of the professional China Blind Rivets manufacturer and China Mushroom Head Break Mandrel Closed End Blind Rivets factory, we are strong strength and complete management. Also, we have own exporting license. We mainly deal in making a series of Blind Rivets and so on. We stick to the principal of quality orientation and customer priority, we sincerely welcome your letters, calls and investigations for business cooperation. We assure you of our high quality services at all time.Type A 12 Point Flange Screw

Type A 12 point flange screws are fasteners with 12 corners on the head with a flange surface. They have many contact points and are not easy to slip when tightened with tools.The bolts produced by Xiaoguo® factory are durable and can withstand harsh working conditions. You can place an order at any time.Blue White Zinc Flat Square Washers

Blue white zinc flat square washers are fasteners with high strength and corrosion resistance.With more than a decade of experience, Xiaoguo® is a factory that can provide customized fasteners to its customers.Type B Large Hexagon Head Flange Bolts

Xiaoguo® produces type B large hexagon head flange bolts in accordance with the Q186-1999 standard. They have high strength and bearing capacity and are not easy to loosen. The shape and size of the thread meet the standard, which enhances stability.They can be used in harsh environments.Round Wing Nut

Round wing nuts have two round wings, like butterfly wings, and can be tightened by hand without too much force. Xiaoguo® provide standard sizes, or customized sizes, and are equipped with nylon washers for shock absorption. Wing nuts and round wing nuts comply with DIN 315 and ANSI B18.13 standards.Type BC Shackle

Type BC shackle is a commonly used shackle, made of recyclable materials. Regular maintenance can extend its service life. Xiaoguo® uses recyclable materials in production and meets relevant standards.