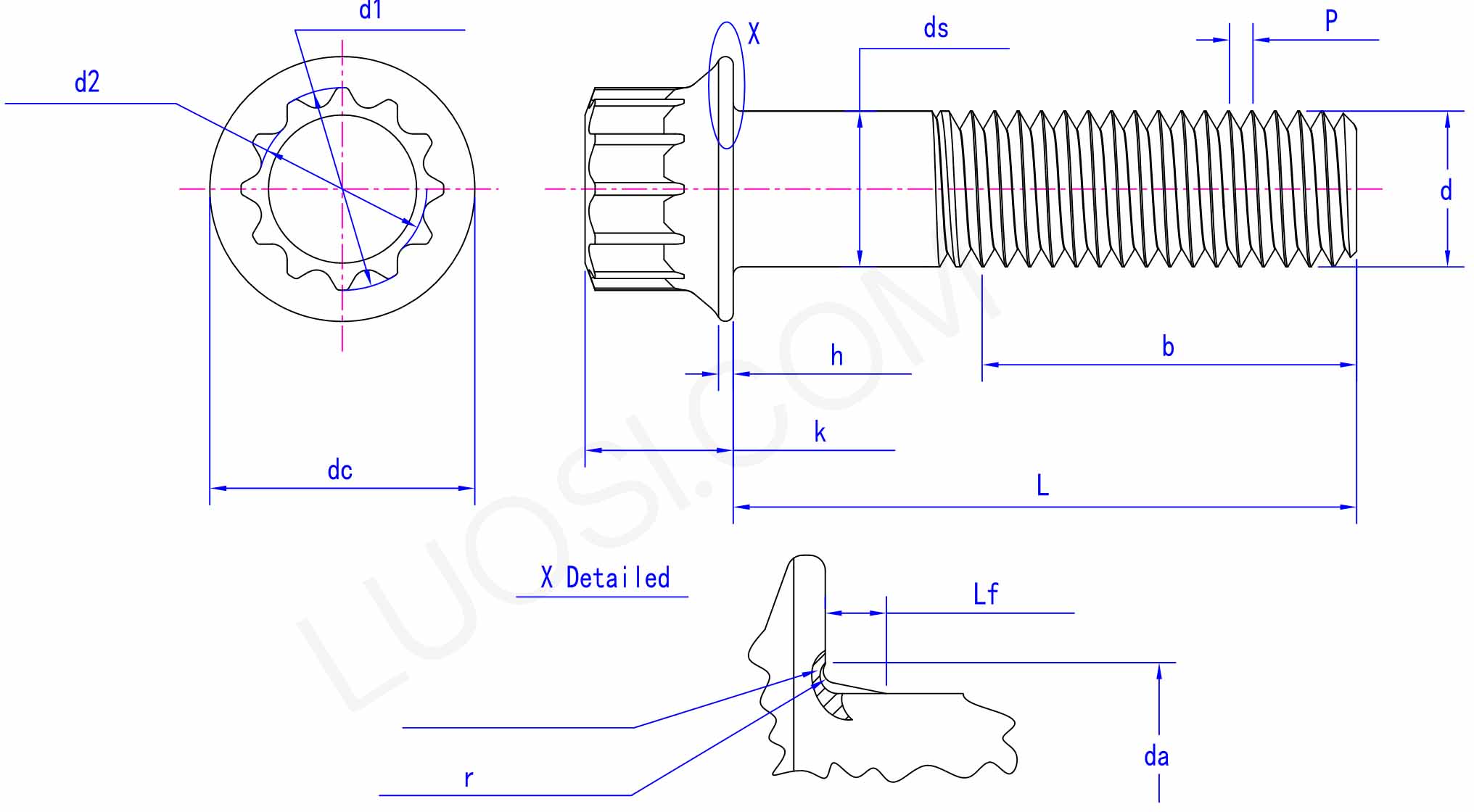

Type A 12 Point Flange Screw

Send Inquiry

The type A 12 point flange screw has 12 corners at the head and can be used in conjunction with a dedicated 12-corner socket wrench. There is a flange plate below the head of the screw. The rod body is cylindrical and has a stepped structure with smooth rod sections and fully threaded sections.

Features

The A type 12-piont flange screws require special sleeves. These 12 sleeve designs allow you to screw them into narrow Spaces where other screws cannot. The built-in flange functions similarly to a gasket, saving you an additional part. It is very convenient for narrow engine compartments or control panels.

Type A 12 point flange screws can accelerate the assembly speed. The flange design does not require a separate gasket, and the 12-angle drive unit is more capable of accepting sleeves at more angles than hexagonal screws. For production lines that manufacture electrical appliances or machinery, the speed is faster.

Type A 12-Piont screws can prevent loosening due to vibration. The flange increases the friction with the surface. It can be used for pumps, compressors or any components that vibrate without the need for locking gaskets. Integrated flanges can reduce height and are highly suitable for electronic devices or precision components.

Product Parameters

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 | M20 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 |

| ds min | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 |

| ds max | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 19.67 |

| dc max | 9.4 | 11.3 | 15 | 18.6 | 22.8 | 26.4 | 30.3 | 37.4 |

| h min | 1.7 | 2.1 | 2.7 | 3.4 | 4.1 | 4.8 | 5.7 | 7.2 |

| k max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 |

| d1 max | 5.86 | 7.02 | 9.37 | 11.7 | 14.04 | 16.29 | 18.71 | 23.4 |

| d1 min | 5.71 | 6.82 | 9.17 | 11.5 | 13.84 | 16.06 | 18.48 | 23.17 |

| d2 max | 5.22 | 6.26 | 8.34 | 10.42 | 12.5 | 14.59 | 16.66 | 20.83 |

| d2 min | 5.07 | 6.06 | 8.14 | 10.22 | 12.3 | 14.36 | 16.43 | 20.6 |

| da max | 6.1 | 7.4 | 10.1 | 12.5 | 15.7 | 18.1 | 20.5 | 26.1 |

| Lf max | 1.4 | 1.6 | 2.1 | 2.1 | 2.1 | 2.1 | 3.2 | 4.2 |

| r max | 0.25 | 0.29 | 0.36 | 0.45 | 0.54 | 0.63 | 0.72 | 0.9 |

| r min | 0.1 | 0.12 | 0.16 | 0.2 | 0.24 | 0.28 | 0.32 | 0.4 |

Advantages

The biggest selling point of type A 12 point flange screw is that they have particularly strong fastening force. Because of the 12-angle head design, when using a socket wrench to tighten, a greater force can be applied to firmly fix the screw in place. Its anti-loosening performance is very obvious on the machines running in the factory and the vehicles in motion. They can reduce safety hazards and equipment failures caused by loosening.