China Countersunk Head Hex Socket Screw Manufacturer, Supplier, Factory

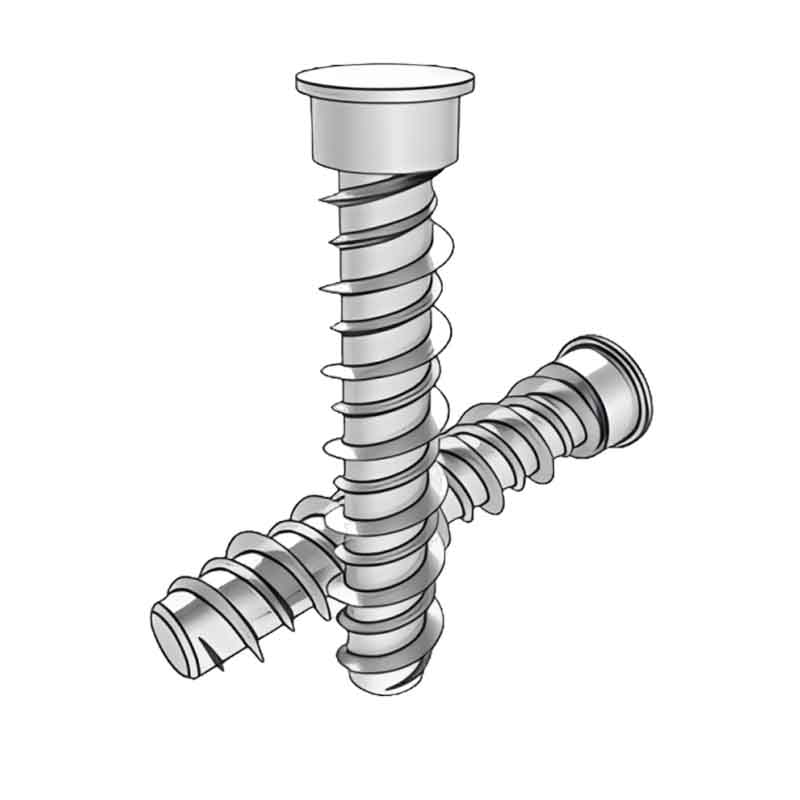

When it comes to high-performance fastening solutions in demanding applications, the Hex Socket Countersunk Head Screws stand out for their precision and reliability. These specialized screws are engineered to provide a flush surface finish, making them ideal for assemblies where a smooth, aerodynamic, or aesthetically pleasing surface is critical. Unlike standard Socket Head Cap Screws, the countersunk head design allows the screw to sit perfectly within a countersunk hole, eliminating any protrusion. The internal hex socket drive, characteristic of a Hexagonal Socket Head Cap Screw, offers superior torque transmission and a high level of security against cam-out, ensuring a tight and secure fit even in high-vibration environments. This combination of features makes these screws a top choice for industries ranging from aerospace and automotive to machinery and high-end consumer electronics.

The Countersunk Head Hex Socket Screw is defined by its meticulous design and robust material specifications. This fastener is manufactured to exacting standards, ensuring consistent performance and dimensional accuracy. Key parameters that define the Countersunk Head Hex Socket Screw are detailed below for clarity and professional specification.

- Head Style: Countersunk (82° or 90° standard included angle)

- Drive Type: Internal Hex Socket

- Thread Type: Metric (e.g., M3, M4, M5, M6, M8) or Imperial (e.g., #4, #6, #8, #10, 1/4")

- Material Grade: Typically available in Stainless Steel (A2/A4), Alloy Steel (Grade 8.8, 10.9, 12.9), and Brass.

- Surface Finish: Plain, Black Oxide, Zinc Plated, or Passivated for corrosion resistance.

- Standards: Commonly conforms to DIN 7991 and ISO 10642 standards.

| Nominal Size (Metric) | Socket Key Size (mm) | Head Diameter (mm) | Head Height (mm) | Typical Tensile Strength (MPa) |

|---|---|---|---|---|

| M3 | 2.0 | 5.7 | 1.65 | 800 (A2-70) |

| M4 | 2.5 | 7.6 | 2.2 | 800 (A2-70) |

| M5 | 3.0 | 9.5 | 2.75 | 800 (A2-70) |

| M6 | 4.0 | 11.5 | 3.3 | 1000 (Grade 10.9) |

| M8 | 5.0 | 15.4 | 4.4 | 1000 (Grade 10.9) |

| Nominal Size (Imperial) | Socket Key Size (inch) | Head Diameter (inch) | Head Height (inch) | Typical Tensile Strength (ksi) |

|---|---|---|---|---|

| #4 | 3/32 | 0.225 | 0.065 | Minimum 70 |

| #6 | 1/8 | 0.270 | 0.086 | Minimum 70 |

| #8 | 5/32 | 0.312 | 0.112 | Minimum 70 |

| #10 | 3/16 | 0.375 | 0.135 | Minimum 70 |

| 1/4" | 1/4 | 0.500 | 0.172 | Minimum 125 |

Hot Products

Stainless Steel Self Clinching Spring Top Standoff

The stainless steel self clinching spring top standoff can withstand high loads and provide a stable and secure connection. Stainless steel is used for the fasteners used to support and fix the components.Xiaoguo® Factory has a variety of fasteners to choose from, making it easy to find the right product.Bolts For T-Slot

Welcome to Baoding Xiaoguo Intelligent Equipment Co., LTD.,to wholesale Bolts for T-Slot, every request from customers is being replied within 24 hours. Xiaoguo is the professional manufacturer, we would like to provide you high quality Bolts for T-Slot and we will offer you the best after-sale service and timely delivery.Petrochemical Hex Bolts With Full Thread

Petrochemical hex bolts with full thread are also called single chamfered hexagon basic nuts, which are made of heat-resistant and corrosion-resistant materials and are used in oil refineries and chemical plants. China Xiaoguo® has stocks of petrochemical full thread hexagonal bolt.Black Heaye Hexagon Nut

The black heaye hexagon nut is suitable for use in the construction, hardware or DIY industry. Buying in bulk from Xiaoguo® will not only save you costs, but also guarantee a stable supply. They are easy to store and distribute. We provide samples.Square Countersunk Head Bolt

Square countersunk head bolt can allow the bolt head to sink into the installation surface, ensuring a smooth and beautiful surface while avoiding protrusions and bumps, making them suitable for occasions that require appearance and safety. If you need a flat surface, you can choose Xiaoguo® this bolt. The countersunk head enables the bolt to adhere smoothly to the surface. We produce bolts of various sizes and they are in stock. You can contact us at any time for inquiries.Oblique head bolt

The oblique head bolt is a common fastener, which is widely used in the fields of machinery manufacturing, construction industry, automobile manufacturing, etc.Through regular communication and feedback from our customers, Xiaoguo® constantly improve our services to ensure the highest level of customer satisfaction.