Precision Engineered Weld Round Nuts

Send Inquiry

Carbon steel is the most common material for Precision Engineered Weld round nuts, and it’s pretty cheap too. It’s strong enough, welds well, and doesn’t cost a lot—so it works for most general industrial and construction jobs.

Carbon steel Precision Engineered Weld round nuts usually come either plain (no plating) because they’re meant to be welded, or with a thin coating to keep them from rusting while they’re stored or handled, before being welded into the final product.

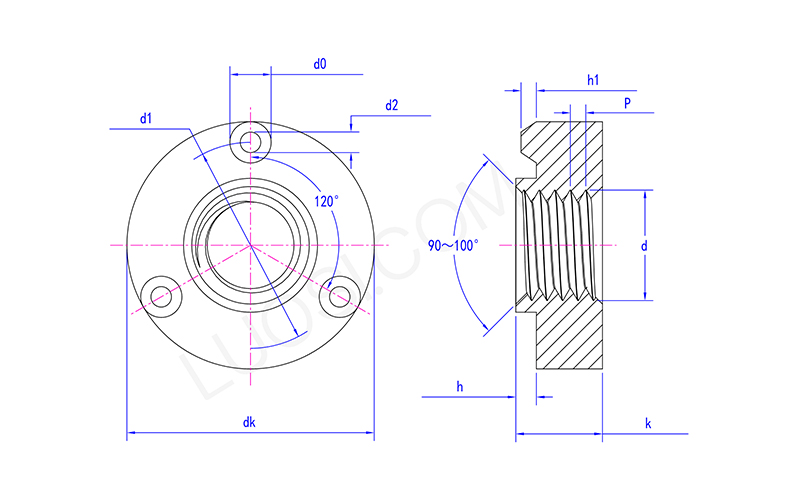

| Mon | M4 | M5 | M6 | M8 | M10 | M12 |

| P | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 |

| d1 max | 10.9 | 11.9 | 13.3 | 17.9 | 19.9 | 22.7 |

| d1 min | 10.5 | 11.5 | 12.9 | 17.5 | 19.5 | 22.3 |

| d0 max | 2.8 | 2.8 | 3.2 | 4.3 | 4.3 | 5 |

| d0 min | 2.5 | 2.5 | 2.9 | 4 | 4 | 4.7 |

| d2 max | 0.95 | 0.95 | 1.5 | 2.1 | 2.1 | 2.5 |

| d2 min | 0.65 | 0.65 | 1.2 | 1.8 | 1.8 | 2.2 |

| dk max | 13.7 | 14.7 | 16.5 | 22.2 | 24.2 | 27.7 |

| dk min | 13.3 | 14.3 | 16.1 | 21.8 | 23.8 | 27.3 |

| h max | 1.35 | 1.35 | 1.55 | 2 | 2 | 2.5 |

| h min | 1.1 | 1.1 | 1.3 | 1.75 | 1.75 | 2.25 |

| h1 max | 0.85 | 0.85 | 1 | 1.5 | 1.5 | 2 |

| h1 min | 0.65 | 0.65 | 0.75 | 1.19 | 1.19 | 1.78 |

| k max | 4.45 | 4.7 | 5.2 | 6.8 | 8.4 | 10.8 |

| k min | 4.15 | 4.4 | 4.9 | 6.44 | 8.04 | 10.37 |

Product Details Introduction

If you need more Weld round nuts, stainless steel would be a better choice - the most common types are 304 and 316. This type of stainless steel will form a thin layer of chromium oxide protective layer on the surface, which can effectively prevent the nut from rusting or being damaged when exposed to water, chemicals or harsh environments.

Stainless steel precision engineered welded round nuts, with their excellent material properties and precision processing technology, have become core components in scenarios such as food and beverage processing plants, marine high-salt environments, and chemical production workshops. They are also a must-have choice in all industrial environments that have strict requirements on fastener durability, corrosion resistance, and long-term stability.

How do you ensure the welding compatibility of your Precision-Engineered Weld round nuts?

Our Precision-Engineered Weld round nuts are designed with either a small projection or a full circular base. That gives a consistent, precise spot where they touch the material for welding.

It makes for strong, clean, reliable attachment—whether you’re using spot welding or other methods. There’s less spatter, and the joint stays secure.