Secure Locking Slotted Locking Round Nut

Send Inquiry

For furniture assembly - especially for the parts that bear high pressure in office chairs and shelving components - this type of Secure Locking Slotted Locking Round Nut is a concealed and safe fixation method. Its circular shape can be flush against the surface, and the slots can be used for adjustment.

We offer very cost-effective options for furniture manufacturers. If the order quantity exceeds 100,000 units, a price discount can be enjoyed. Common surface treatments include galvanization or black. We provide a low-cost centralized transportation service.

We ensure quality by conducting batch tests on thread integrity and locking performance. Therefore, these nuts are reliable during use.

Strong product and favorable price

The construction industry uses Secure Locking Slotted Locking Round Nut for structural steel connections and scaffolding - safety is the primary consideration. These nuts are usually of larger diameter and are made of high-strength steel.

We offer exclusive discounts for large projects. Orders over 20,000 pieces receive a 10% price discount, effectively reducing your overall project procurement costs. Hot-dip galvanizing treatment is the standard treatment for weathering steel. We can provide reliable delivery services to the construction site.

We understand the importance of reliability. Therefore, every structural fastener not only comes with sturdy, waterproof packaging, but also meets strict ASTM or DIN standards from the source, ensuring consistent quality and providing foolproof protection for your project.

Provide customized services

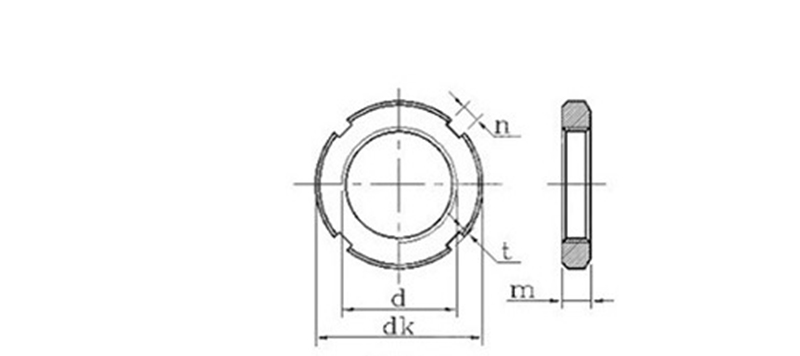

We specialize in producing custom Secure Locking Slotted Locking Round Nut solutions tailored to specific requirements. We can modify dimensions, slot configurations, and material specifications for the Secure-Locking Slotted locking round nut to match your unique application needs. Our engineering team will work with you to develop the perfect Secure-Locking Slotted locking round nut design for your assembly requirements.

|

d*P |

dk | m | n | t |

1000 kg |

d*P |

dk | m | n | t |

1000 ≈kg |

|||||

| nax | nin | max | min | max | min | nax | min | |||||||||

| M10*1 | 22 | 8 | 4.3 | 4 | 2.6 | 2 | 16.82 | M64*2 | 95 | 12 | 8.36 | 8 | 4.25 | 3.5 | 351.9 | |

| M12*1.25 | 25 | 21.58 | M65*2 | 95 | 342.4 | |||||||||||

| M14*1.5 | 28 | 26.82 | M68*2 | 100 | 10.36 | 10 | 4.75 | 4 | 380.2 | |||||||

| M16*1.5 | 30 | 5.3 | 5 | 3.1 | 2.5 | 28.44 | M72*2 | 105 | 15 | 518 | ||||||

| M18*1.5 | 32 | 31.19 | M75*2 | 105 | 477.5 | |||||||||||

| M20*1.5 | 35 | 37.31 | M76*2 | 110 | 562.4 | |||||||||||

| M22*1.5 | 38 | 10 | 54.91 | M80*2 | 115 | 608.4 | ||||||||||

| M24*1.5 | 42 | 68.88 | M85*2 | 120 | 640.6 | |||||||||||

| M25*1.5 | 42 | 68.88 | M90*2 | 125 | 18 | 12.43 | 12 | 5.75 | 5 | 796.1 | ||||||

| M27*1.5 | 45 | 75.49 | M95*2 | 130 | 834.7 | |||||||||||

| M30*1.5 | 48 | 82.11 | M100*2 | 135 | 873.3 | |||||||||||

| M33*1.5 | 52 | 6.3 | 6 | 3.6 | 3 | 93.32 | M105*2 | 140 | 895 | |||||||

| M35*1.5 | 52 | 84.99 | M110*2 | 150 | 14.43 | 14 | 6.75 | 6 | 1076 | |||||||

| M36*1.5 | 55 | 100.3 | 115*2 | 155 | 22 | 1369 | ||||||||||

| M39*1.5 | 58 | 107.3 | M120*2 | 160 | 1423 | |||||||||||

| M40*1.5 | 58 | 109.5 | M125*2 | 165 | 1477 | |||||||||||

| M42*1.5 | 62 | 121.8 | M130*2 | 170 | 1531 | |||||||||||

| M45*1.5 | 68 | 153.6 | M140*2 | 180 | 26 | 1937 | ||||||||||

| M48*1.5 | 72 | 12 | 8.36 | 8 | 4.25 | 3.5 | 201.2 | M150*2 | 200 | 16.43 | 16 | 7.9 | 7 | 2651 | ||

| M50*1.5 | 72 | 186.8 | M160*3 | 210 | 2810 | |||||||||||

| M52*1.5 | 78 | 238 | M170*3 | 220 | 2970 | |||||||||||

| M55*2 | 78 | 214.4 | M180*3 | 230 | 30 | 3610 | ||||||||||

| M56*2 | 85 | 290.1 | 190*3 | 240 | 3794 | |||||||||||

| M60*2 | 90 | 320.3 | M200*3 | 250 | 3978 | |||||||||||