Mission Critical Aircraft Steel Wire Rope

Send Inquiry

The Mission Critical Aircraft Steel Wire Rope is a crucial component in the main and auxiliary flight control systems of many aircraft. It is used to drive mechanical devices such as the elevators, ailerons, and rudders.

It must be strong, manufactured precisely, and have a predictable fatigue life under bending - these factors are important because they ensure that the pilot's instructions can be accurately and reliably transmitted to the control surfaces. If the aircraft wire rope fails at this point, the consequences could be catastrophic.

This is also the core reason why the manufacturing, testing and installation of aircraft wire ropes must strictly comply with the highest standards of the Aviation Administration, and no link must deviate from the specification requirements. The aim is to ensure their perfect operation and guarantee flight safety.

Product Benefits

In the landing gear system and emergency braking system, the steel cables used in aircraft typically serve as reliable mechanical connectors or backup safety ropes.

The design of these steel cables is capable of withstanding the tremendous tension and sudden impacts during aircraft landing, takeoff, or forced aborted takeoff. The specific type of aircraft steel cables used here have excellent wear resistance and fatigue resistance - thus it can maintain a good condition for thousands of flight cycles, performing its important role without deteriorating.

Operators must be certified and undergo special training before taking up their posts. They must follow the manual and conduct mutual inspections on key steps such as wheel chock placement and bridge docking.

Comply with international standards

Mission Critical Aircraft Steel Wire Rope must comply with stringent international standards such as MIL-SPEC (e.g., MIL-W-83420) or AMS (Aerospace Material Standards). These certifications are a strong guarantee for the excellent performance of aircraft critical wire ropes in terms of fatigue resistance, tensile strength and operational safety. Our products undergo strict testing and provide full traceability documentation to meet aviation industry demands.

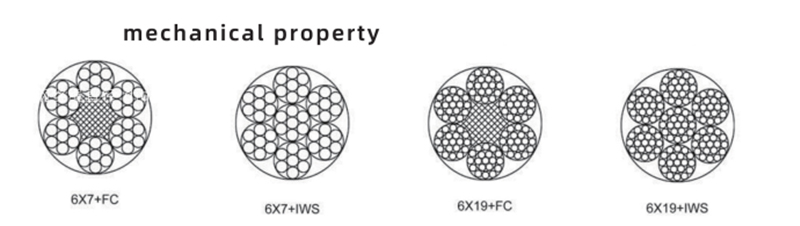

Product Parameters

|

Diameter mm |

nominal tensile strength |

minimun breaking loa |

approximate weight kg/100m |

|

| nominal diameter | allowed tolerance | |||

|

6x7+FC |

||||

| 1.8 | +100 | 1960 | 2.3 | 1.40 |

| 2.15 |

+80 |

1960 |

3.3 | 2.00 |

| 2.5 | 4.5 | 2.70 | ||

| 3.05 |

1870 |

6.3 | 4.00 | |

| 3.6 | 8.7 | 5.50 | ||

| 4.1 |

+70 |

1770 |

10.4 | 7.00 |

| 4.5 | 12.8 | 8.70 | ||

| 5.4 | 1670 | 17.5 | 12.50 | |

|

6x7+IWS |

||||

| 1.8 | +100 |

1870 |

2.5 | 1.50 |

| 2.15 |

+80 |

3.6 | 2.20 | |

| 2.5 | 5.0 | 3.00 | ||

| 3.05 | 7.3 | 4.40 | ||

| 3.6 | 10.1 | 6.20 | ||

| 4.5 |

+70 |

1770 | 15.0 | 9.60 |

| 5.4 | 1670 | 20.4 | 13.80 | |

|

6x19+FC |

||||

| 3 |

+80 |

2.060 | 6.3 | 3.80 |

| 3.3 | 1770 | 6.5 | 4.50 | |

| 3.6 | 7.8 | 5.40 | ||

| 4.2 |

+30 |

10.6 | 7.40 | |

| 4.8 | 12.9 | 9.00 | ||

| 5.1 | 15.6 | 10.90 | ||

| 6.2 | 1670 | 20.3 | 15.00 | |

|

6x19+IWS |

||||

| 3 | +80 | 2060 | 7.3 | 4.20 |

| 3.2 | 2160 | 8.9 | 4.30 | |

| 3.6 |

1700 |

9.1 | 6.00 | |

| 4.2 |

+70 |

12.3 | 8.20 | |

| 5.1 | 18.2 | 12.10 | ||

| 6 |

1670 |

23.7 | 16.70 | |

| 7.5 |

+50 |

37.1 | 26.00 | |

| 8.25 | 44.9 | 32.00 | ||

| 9 | 53.4 | 37.60 | ||

| 9.75 | 62.6 | 44.10 | ||