Extremely Durable Aircraft Steel Wire Rope

Send Inquiry

The packaging design of the Extremely Durable Aircraft Steel Wire Rope is intended to provide it with excellent protection and meet high standards.

Each steel wire rope is carefully wound onto its own sturdy reel. Then we place these reels into a cardboard or wooden box of the same size. We also ensure that the reels do not shake inside the box during transportation. This meticulous packaging of the aircraft's steel wire rope is designed to handle all the unfavorable factors during transportation and handling. Thus, when it reaches you, it will be in perfect condition - without any distortion and ready for immediate installation and use.

Product Details

If the aircraft is properly wrapped with steel wire, the possibility of damage during transportation will be extremely low.

The special aviation-grade packaging we use is designed to protect the product - to prevent it from being impacted, flattened or getting damp. Moreover, the steel wire itself is very sturdy and can withstand damage on its own. Therefore, you can rest assured that the aircraft steel wire you ordered will have no structural or surface issues when delivered. As a result, it will maintain all the certified performance it should have.

Product Details

|

Diameter mm |

Nominal tensile strength |

Minimun breaking loa |

Approximate weight kg/100m |

|

| Nominal diameter | Allowed tolerance | |||

|

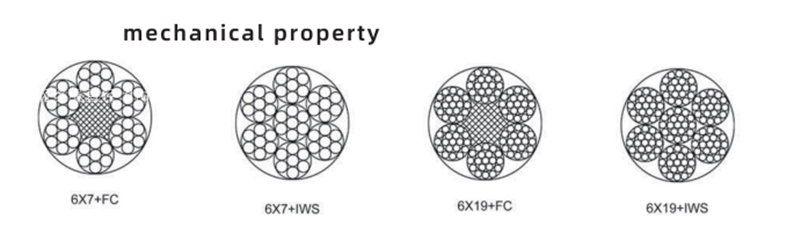

6x7+FC |

||||

| 1.8 | +100 | 1960 | 2.3 | 1.40 |

| 2.15 |

+80 |

1960 | 3.3 | 2.00 |

| 2.5 | 4.5 | 2.70 | ||

| 3.05 |

1870 |

6.3 | 4.00 | |

| 3.6 | 8.7 | 5.50 | ||

| 4.1 |

+70 |

1770 |

10.4 | 7.00 |

| 4.5 | 12.8 | 8.70 | ||

| 5.4 | 1670 | 17.5 | 12.50 | |

|

6x7+IWS |

||||

| 1.8 | +100 |

1870 |

2.5 | 1.50 |

| 2.15 |

+80 |

3.6 | 2.20 | |

| 2.5 | 5.0 | 3.00 | ||

| 3.05 | 7.3 | 4.40 | ||

| 3.6 | 10.1 | 6.20 | ||

| 4.5 |

+70 |

1770 | 15.0 | 9.60 |

| 5.4 | 1670 | 20.4 | 13.80 | |

|

6x19+FC |

||||

| 3 |

+80 |

2060 | 6.3 | 3.80 |

| 3.3 |

1770 |

6.5 | 4.50 | |

| 3.6 | 7.8 | 5.40 | ||

| 4.2 |

+30 |

10.6 | 7.40 | |

| 4.8 | 12.9 | 9.00 | ||

| 5.1 | 15.6 | 10.90 | ||

| 6.2 | 1670 | 20.30 | 15.00 | |

|

6x19+IWS |

||||

| 3 |

+80 |

2060 | 7.3 | 4.20 |

| 3.2 | 2160 | 8.9 | 4.30 | |

| 3.6 |

1770 |

9.1 | 6.00 | |

| 4.2 |

+70 |

12.3 | 8.20 | |

| 5.1 | 18.2 | 12.10 | ||

| 6 |

1670 |

23.7 | 16.70 | |

| 7.5 |

+50 |

37.1 | 26.00 | |

| 8.25 | 44.9 | 32.00 | ||

| 9 | 53.4 | 37.60 | ||

| 9.75 | 62.6 | 44.10 | ||

FAQ

Q:What maintenance and inspection protocols do you recommend?

A: Regular inspection of Extremely-Durable Aircraft steel wire rope is essential for airworthiness. Check for broken wires, corrosion, and wear at contact points. Lubrication with aviation-grade lubricant reduces internal friction. To ensure continued safety and performance, replace your ultra-durable aircraft wire rope immediately if you notice any signs of damage. Follow the detailed maintenance instructions.