Lock Washers

Send Inquiry

Lock washers (also called circlips or circlips) are simple auxiliary parts that snap into grooves to secure components. They can replace screws or bolts to prevent parts from sliding along shafts or holes, and are relatively lighter and more economical.

This type of retaining ring is often used in everyday machines (such as automobiles, rotating equipment and factory tools). It is easy and quick to install and remove. There are two different types: one is installed in a groove (internal), and the other is wrapped around the external part (external). They are mainly used to fix bearings, gears or shafts. Most of the retaining rings produced by Xiaoguo® adopt standard sizes that are commonly used worldwide, so they can be used with parts of standard sizes.

Features

Lock washers are easy to use, have a strong load-bearing capacity, and do not take up space. They are simpler and lighter than screws or bolts, and can firmly fix parts even under stress. They have a strong grip to prevent parts from loosening and are suitable for use on vibrating machines.

Choose washers of different sizes and materials (stainless steel, coated materials, etc.) according to requirements such as heat resistance, rust resistance or high-intensity use. When installing or checking and replacing, ordinary pliers can be used, which is convenient and quick. It is often used in industries such as automobiles, aircraft or factory equipment that have high requirements on fastening effect and precision.

Materials

What materials can I choose for lock washers?

Lock washers are made of high carbon steel, stainless steel or beryllium copper. High carbon steel is a strong material that can withstand heavy loads. Stainless steel is suitable for wet or chemical environments and will not rust. Beryllium copper is suitable for electrical work or situations where sparks may be generated. It conducts electricity and is non-magnetic.

Depending on the material you choose, the results will vary in terms of the pressure, weight, temperature resistance and service life. For example, heat-treated carbon steel can withstand greater strain, but in wet environments, it needs to be zinc-dipped to prevent rust.

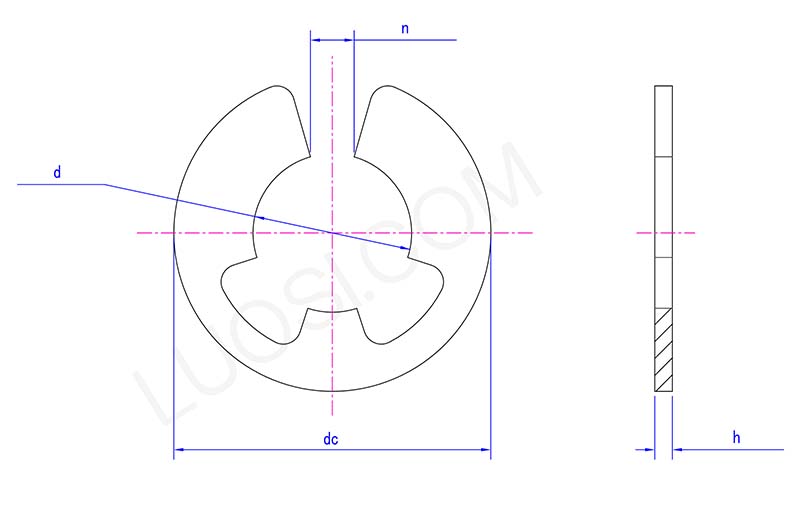

|

Mon |

Φ5 |

Φ6 |

Φ7 |

Φ8 |

Φ9 |

Φ10 |

Φ12 |

Φ15 |

Φ19 |

Φ24 |

Φ30 |

|

d max |

5 | 6 | 7 | 8 | 9 | 10 | 12 | 15 | 19 | 24 | 30 |

|

d min |

4.925 | 5.925 | 6.91 | 7.91 | 8.91 | 9.91 | 11.89 | 14.89 | 18.87 | 23.87 | 29.87 |

|

h max |

0.72 | 0.72 | 0.92 | 1.03 | 1.13 | 1.23 | 1.33 | 1.53 | 1.78 | 2.03 | 2.53 |

|

h min |

0.68 | 0.68 | 0.88 | 0.97 | 1.07 | 1.17 | 1.27 | 1.47 | 1.72 | 1.97 | 2.47 |

|

n max |

4.158 | 5.308 | 5.888 | 6.578 | 7.688 | 8.378 | 10.52 | 12.68 | 15.99 | 21.964 | 25.884 |

|

n min |

4.062 | 5.212 | 5.792 | 6.462 | 7.572 | 8.262 | 10.38 | 12.54 | 15.85 | 21.796 | 25.716 |

|

dc max |

11.3 | 12.3 | 14.3 | 16.3 | 18.8 | 20.4 | 23.4 | 29.4 | 37.6 | 44.6 | 52.6 |