E Type Snap Ring

Send Inquiry

This E type snap ring is an internal retaining ring,it come in different materials to fit different jobs. Stainless steel types like 304 or 316 are good for wet or chemical-heavy areas. The harder 410-grade steel holds up better under wear. Carbon steel rings are cheaper but still strong, especially with a rust-proof coating. Beryllium copper works for electrical jobs or flammable areas since it won’t spark. Plastic ones (like nylon) resist chemicals and cut down on noise in lighter setups. For really harsh factories, tougher metals like Hastelloy® or Monel® get used. Most of these materials are checked for safety and eco-rules (like RoHS), so they’re okay for regulated industries.

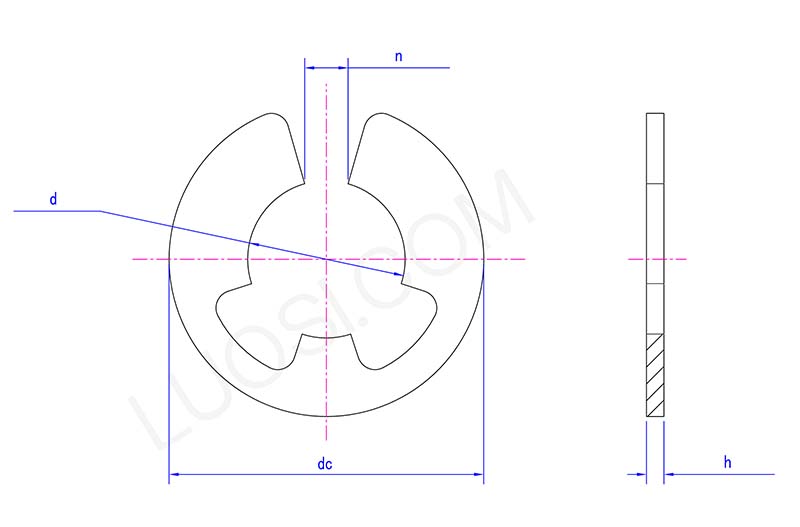

Mon

Φ5

Φ6

Φ7

Φ8

Φ9

Φ10

Φ12

Φ15

Φ19

Φ24

Φ30

d max

5

6

7

8

9

10

12

15

19

24

30

d min

4.925

5.925

6.91

7.91

8.91

9.91

11.89

14.89

18.87

23.87

29.87

h max

0.72

0.72

0.92

1.03

1.13

1.23

1.33

1.53

1.78

2.03

2.53

h min

0.68

0.68

0.88

0.97

1.07

1.17

1.27

1.47

1.72

1.97

2.47

n max

4.158

5.308

5.888

6.578

7.688

8.378

10.52

12.68

15.99

21.964

25.884

n min

4.062

5.212

5.792

6.462

7.572

8.262

10.38

12.54

15.85

21.796

25.716

dc max

11.3

12.3

14.3

16.3

18.8

20.4

23.4

29.4

37.6

44.6

52.6

Regular inspection and maintenance

To make E type snap ring last longer, check them now and then for rust, cracks, or bending,especially in heavy-use machines. Keep their grooves clean so dirt doesn’t mess with how they fit. If there’s lots of rubbing, add grease to help things slide smoother.

When installing, avoid over-stretching or squishing them too hard,that weakens the ring over time. If you spot damage, swap them out. Store extras in a dry spot (not too hot or cold) to keep the material from degrading. Use snap ring pliers for safer handling.

Impact of environmental factors

Q: How do environmental factors like temperature or moisture impact internal retaining ring performance?

A:If you choose the wrong material, high heat or humidity can mess up E type snap ring.Carbon steel rings (the stronger ones) will rust in wet areas unless they have a rust-resistant coating. Stainless steels (such as the common 304/316 grades) resist moisture well but begin to lose strength above 400°C. Some stainless steels or specialty metals remain flexible at freezing temperatures. If chemicals such as acids or solvents are involved, choose a non-reactive coating (such as Teflon).

We have a professional team that can recommend suitable products based on usage scenarios and requirements, and also provide customized services.