E Type Retaining Rings

Send Inquiry

Mon

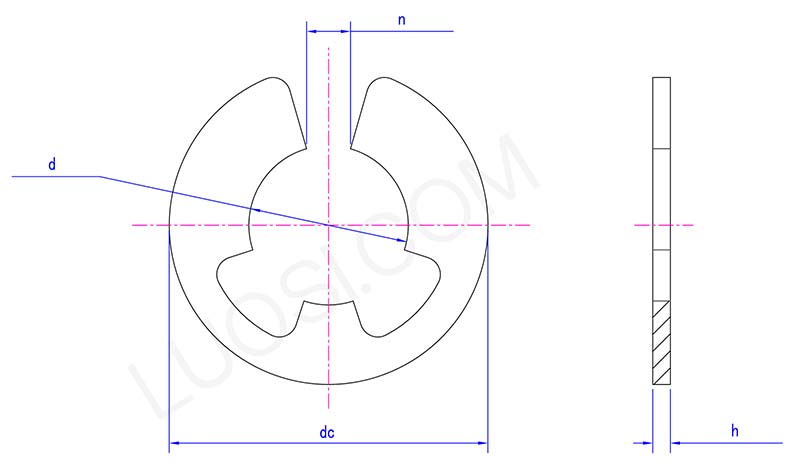

Φ2

Φ2.5

Φ3

Φ3.5

Φ4

Φ5

Φ6

Φ8

Φ9

Φ12

Φ15

d max

2

2.5

3

3.5

4

5

6

8

9

12

15

d min

1.86

2.36

2.86

3.32

3.82

4.82

5.82

7.78

8.78

11.73

14.73

n max

1.825

2.325

2.625

3.125

3.65

4.65

5.65

7.68

8.18

10.715

13.215

n min

1.575

2.075

2.375

2.875

3.35

4.35

5.35

7.32

7.82

10.285

12.785

h max

0.43

0.43

0.64

0.64

0.84

0.84

1.05

1.05

1.05

1.25

1.56

h min

0.34

0.34

0.53

0.53

0.7

0.7

0.87

0.87

0.87

1.07

1.35

dc max

5

6

7

8

9

10

12

16

18

24

30

E type retaining rings make putting things together easier because you can install them with no tools or just a few simple ones.Circlip pliers can quickly insert or remove them, with short usage time and low cost. This retaining ring is a split ring that can be slightly bent to fit snugly into the groove when installed in the right position. Unlike screws or bolts, they do not require thread processing, so there is less chance of damaging the parts during assembly.

These rings can withstand loads that change over time, such as vibration or when parts expand due to heat, and stay in place. Plus, they are reusable, which makes replacing components much simpler. Easy installation, no specialized training required, and quick changeovers on busy production line equipment. Flat shape fits into tight spaces.

Standard

E type retaining rings have strict industry certifications for quality and safety. ISO 8750-8752 sets the rules for external ring sizes, while DIN 472/471 applies to internal ones. Rings used in aerospace meet AS9100 standards, which help track their quality and ensure they work well in tough conditions. Medical-grade materials follow FDA and USP Class VI guidelines. RoHS and REACH certifications make sure they’re produced in an eco-friendly way.

We offer material test reports (MTRs) and PPAP docs for important uses.

What quality certifications are available?

Xiaoguo® is a professional E type retaining rings manufacturer that produces products in accordance with international standards such as ISO 9001 (quality management), ISO/TS 16949 (automotive industry) or AS9100 (aerospace industry). The materials we use are consistent with the standards, and the manufactured parts meet the standards and the errors are within the standard range. The finished products will be tested after production, and some require salt spray testing or load durability testing. We can provide material test reports that meet ASTM or DIN specifications. We have also obtained NADCAP certification, a relevant standard for products suitable for aerospace use.

In industries with high safety requirements, retaining rings need to undergo comprehensive size, surface defects and hardness (in Rockwell C hardness units). Reduce the use of non-standard parts.