E Circlip

Send Inquiry

There are many materials to choose from for E Circlips, such as stainless steel, carbon steel, aluminum or titanium alloy, etc. Choose the right material according to different needs and scenarios. Stainless steel elastic retaining rings are rust-proof and corrosion-resistant, and are more suitable for use in marine or chemical environments. Carbon steel elastic retaining rings are heat-treated to have higher hardness, thus having higher tensile strength, and are suitable for heavy machinery.Aluminum or titanium alloy elastic retaining ring is a lightweight retaining ring that is strong and durable.Inconel® is an alloy that can withstand extreme temperatures and is suitable for use in aerospace or energy fields. Choosing the right material can reduce unnecessary costs, reduce the frequency of replacement, and is wear-resistant and durable. Xiaoguo® manufactures in accordance with industry standards such as DIN, ISO and ANSI, and the quality is guaranteed.

Application

E circlips are super useful in mechanical setups where you need to keep parts firmly in place. They hold bearings inside motors, gears in transmissions, and pistons in hydraulic systems. For cars, they’re used in axle setups and brake systems, while in factories, you’ll find them in conveyor belts and pump shafts. In electronics, tiny retaining rings keep connectors from moving around. They even work in green energy setups, like the gear boxes in wind turbines. By stopping parts from sliding axially, these rings make machines run more steadily, cut down on maintenance time, and make equipment last longer in lots of fields,like robotics, medical gadgets, and heavy machinery.

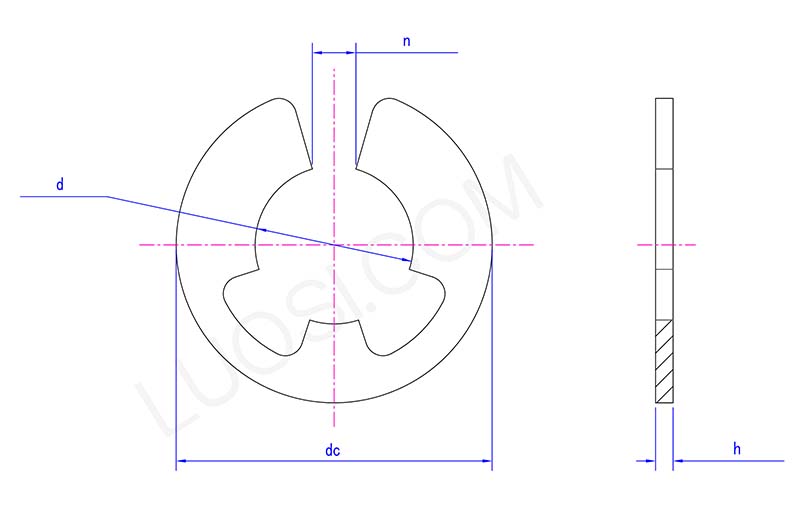

Size

Q:How to choose the appropriate E-type circlip size and type?

A: When picking the right Circlip, you need to look at the size of the bore or shaft, the groove specs, and how much axial load it needs to handle. Use proper tools to measure the shaft/bore diameter and groove depth/width accurately. Check Xiaoguo® guides or charts (like DIN 471/472 or ANSI B27.1) to match these measurements with standard ring sizes.

For custom setups, think about whether the load is steady or changes over time. Spiral rings are better for loads that push in different directions, while tapered rings work well for high-speed spinning parts. If you’re not sure, can ask us about doing FEA testing to make sure the ring can handle the stresses of the job.

Getting the size wrong is a big deal,it can make the ring bend, damage the groove, or even cause the whole assembly to fail. So take the time to measure carefully and match the ring to what the job needs.

Mon

Φ2

Φ2.5

Φ3

Φ3.5

Φ4

Φ5

Φ6

Φ8

Φ9

Φ12

Φ15

d max

2

2.5

3

3.5

4

5

6

8

9

12

15

d min

1.86

2.36

2.86

3.32

3.82

4.82

5.82

7.78

8.78

11.73

14.73

n max

1.825

2.325

2.625

3.125

3.65

4.65

5.65

7.68

8.18

10.715

13.215

n min

1.575

2.075

2.375

2.875

3.35

4.35

5.35

7.32

7.82

10.285

12.785

h max

0.4

0.4

0.6

0.6

0.8

0.8

1

1

1

1.2

1.5

h min

0.36

0.36

0.55

0.55

0.73

0.73

0.91

0.91

0.91

1.11

1.39

dc max

5

6

7

8

9

10

12

16

18

24

30