E Type Retaining Ring

Send Inquiry

Surface treatments for E type retaining ring help them work better in tough conditions. Zinc plating gives basic corrosion protection for use indoors, while phosphate coatings make them more resistant to wear and smoother. Electropolished stainless steel rings stop pitting in chemical environments. In high-temperature spots, black oxide coatings cut down friction and keep them from getting stuck due to wear. Special treatments like Xylan® or Teflon® add non-stick features and electrical insulation. You can choose finishes based on what you need, balancing cost and how long they last. These treatments make them last longer and keep their size accurate even under stress.

Size

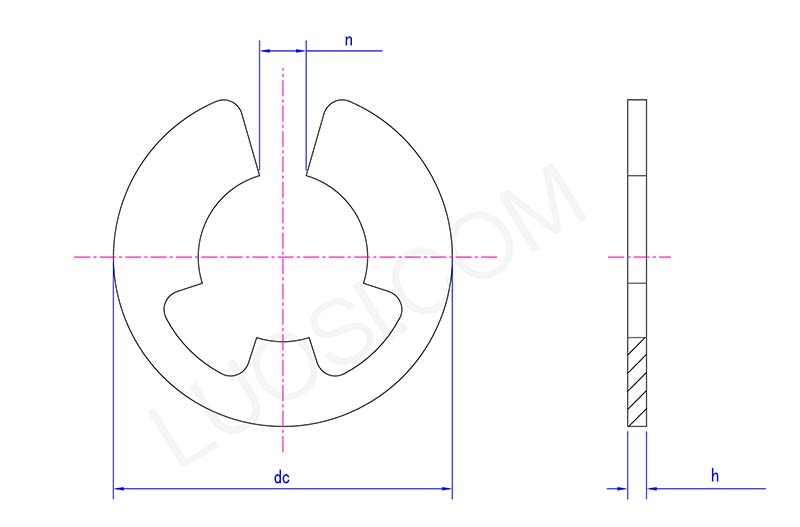

E type retaining rings are available in standard and custom sizes for grooves ranging from 1 mm to 300 mm in diameter. Inner retaining rings are suitable for parts installed in holes, while outer retaining rings are suitable for shafts. There are two standard sizes, metric and imperial, which meet global engineering standards. The dimensional tolerance is tight (± 0.05 mm) to ensure a tight fit without slipping. Xiaogu® provides detailed charts listing the thickness, width and required groove size of the retaining ring. If you have a non-standard configuration, you can custom design the retaining ring so that it can be smoothly installed on special machinery, robots or microelectronic devices.

Mon

Φ4

Φ5

Φ6

Φ7

Φ8

Φ9

Φ10

Φ12

Φ15

Φ19

Φ24

dc

9

11

12

14

16

18.5

20

23

29

37

44

n

3.34

4.11

5.26

5.84

6.52

7.63

8.32

10.45

12.61

15.92

21.88

h max

0.72

0.72

0.72

0.92

1.03

1.13

1.23

1.33

1.53

1.78

2.03

h min

0.68

0.68

0.68

0.88

0.97

1.07

1.17

1.27

1.47

1.72

1.97

Can it be reused?

A: Whether you can reuse E type retaining ring depends on how strong the material is and how they have been installed before. If you take them off carefully without bending them,like using the right pliers,you might be able to reuse them in situations where the stress is low and it,s not a critical part. But if you install and remove them a lot, the ring,s ability to stretch back might wear out, and it won,t hold as much weight anymore.

In setups that need high precision or where safety is a big deal,like in aerospace or cars,you should always replace retaining rings after taking them apart. This helps avoid them breaking down from repeated use. When checking used rings, look closely for cracks, wear, or any permanent bends, maybe with a magnifying tool.

It is not recommended to reuse the outer retaining ring. During the disassembly process, the retaining ring may be damaged, which will affect its use. Rechecking and replacing the retaining ring is a waste of time and may damage the connection position. In some cases, the retaining ring can be reused, but it needs to be in the case that the retaining ring is not damaged.