Internal Thread Weld Studs

Send Inquiry

Application:

Internal thread weld studs are used all over heavy industry. Big uses include shipbuilding,securing decks, bulkheads, insulation. In construction, they’re for connecting rebar, attaching cladding, holding services in place. For bridge building, they work for diaphragm connections, bearing attachments. And in power generation, they’re used on boiler casings, ductwork, cable management. They’re fast and strong, so they’re a must for putting up big steel structures and setting up industrial plants efficiently and dependably.

The auto industry uses a lot of internal thread weld studs. They’re used in body-in-white work, to attach trim panels, wiring harnesses, sound insulation, brake lines, fuel lines, and heat shields. Using them makes assembly lines go faster, and they give solid anchor points on thin sheet metal. Same with railway carriages, truck trailers, and farm machinery,they use weld studs a lot to attach panels and mount parts, mostly because they hold up well against vibrations.

Quality assurance:

We make sure our internal thread weld studs work reliably by checking them really carefully. That means we strictly inspect the materials when they come in, check that all the sizes are right, do regular tests where we bend or pull them to break (to see how strong they are), and test how well they weld using standard settings. We can track each batch too, so we can make sure every shipment of weld studs we send out is reliable.

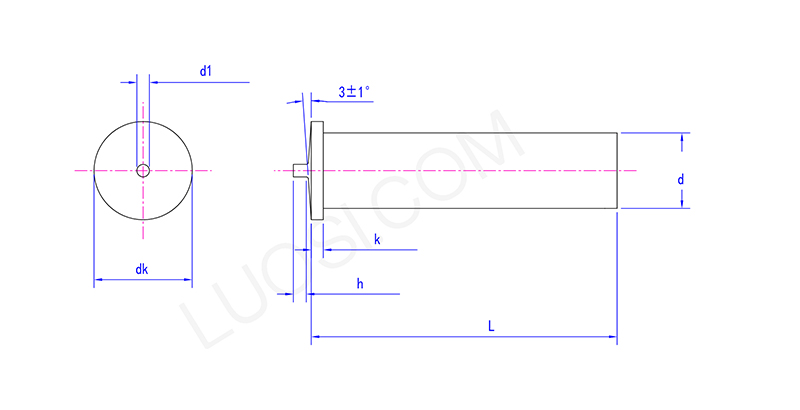

| Mon |

Φ3 |

Φ4 |

Φ5 |

Φ6 |

| d max | 3.1 | 4.1 | 5.1 | 6.1 |

| d min | 2.9 | 3.9 | 4.9 | 5.9 |

| dk max | 4.7 | 5.7 | 6.7 | 7.7 |

| dk min | 4.3 | 5.3 | 6.3 | 7.3 |

| d1 max | 0.68 | 0.73 | 0.83 | 0.83 |

| d1 min | 0.52 | 0.57 | 0.67 | 0.67 |

| h max | 0.6 | 0.6 | 0.85 | 0.85 |

| h min | 0.5 | 0.5 | 0.75 | 0.75 |

| k max | 1.4 | 1.4 | 1.4 | 1.4 |

| k min | 0.7 | 0.7 | 0.8 | 0.8 |