Internal Thread Weld Stud

Send Inquiry

In appliance making,like ovens, fridges, washing machines,the internal thread weld stud hold outer panels, internal brackets, insulation, and wiring tubes in place, and they do it cleanly and efficiently. For electronics cases, control panels, and switchgear, they provide strong threaded spots to attach grounding straps, mount circuit boards, and fasten parts. This keeps things electrically safe and mechanically stable without messing up the case's structure.

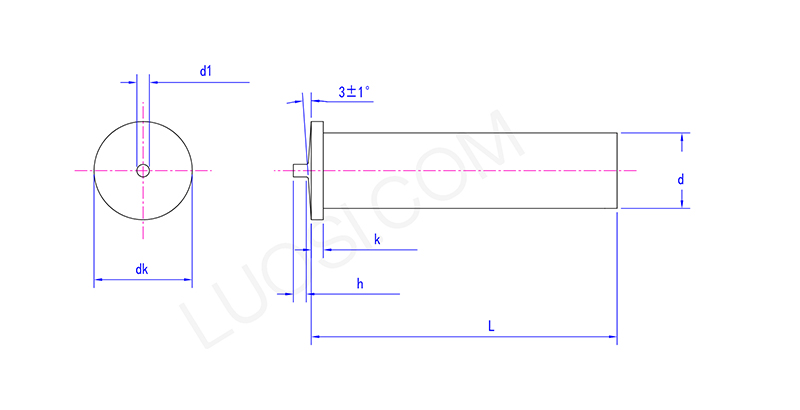

| Mon |

Φ3 |

Φ4 |

Φ5 |

Φ6 |

| d max | 3.1 | 4.1 | 5.1 | 6.1 |

| d min | 2.9 | 3.9 | 4.9 | 5.9 |

| dk max | 4.7 | 5.7 | 6.7 | 7.7 |

| dk min | 4.3 | 5.3 | 6.3 | 7.3 |

| d1 max | 0.68 | 0.73 | 0.83 | 0.82 |

| d1 min | 0.52 | 0.57 | 0.67 | 0.67 |

| h max | 0.6 | 0.6 | 0.85 | 0.85 |

| h min | 0.5 | 0.5 | 0.75 | 0.75 |

| k max | 1.4 | 1.4 | 1.4 | 1.4 |

| k min | 0.7 | 0.7 | 0.8 | 0.8 |

Surface treatment methods:

Internal thread weld studs are usually subjected to surface treatment to enhance their service life. Common treatment methods include galvanization,which can be either electroplated or mechanically deposited. This is a cost-effective approach that provides basic rust prevention capabilities for them. In more severe use scenarios, the protrusions can be treated with coatings or simply made of stainless steel. In this case, you need to select a coating that is compatible and suitable for the welding process, and ensure that the selected material or coating is suitable for the installation location and use scenario of the protrusions. This way, they can be as durable as possible.

Minimum Order Quantity and Discounts:

For most internal thread weld studs, the usual time to get them ready (FOB) after you confirm the order is 25 to 35 days. Our standard export minimum order is usually one case or one pallet, but this can fluctuate, especially for some sizes we have high volumes of.If you order a lot, you might get better prices, and we’ll prioritize making and shipping them.