High Strength Internal Thread Weld Studs

Send Inquiry

High strength internal thread weld studs offer excellent rust resistance.It is able to ensure structural stability and safety in harsh environments such as chemical plants and marine environments due to its excellent rust-proof properties. Welding stainless steel studs requires specific settings and sometimes the use of shielding gas is necessary to prevent the weld area from losing its rust-proof properties.Its performance advantages and process requirements together determine its reliable application in complex environments.

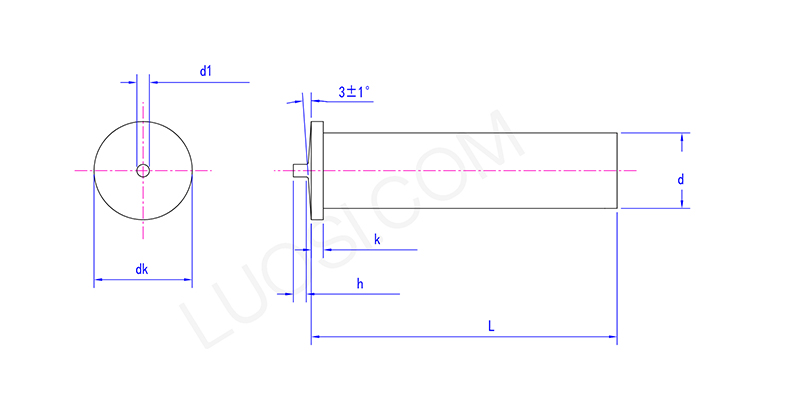

| Mon |

Φ3 |

Φ4 |

Φ5 |

Φ6 |

| d max | 3.1 | 4.1 | 5.1 | 6.1 |

| d min | 2.9 | 3.9 | 4.9 | 5.9 |

| dk max | 4.7 | 5.7 | 6.7 | 7.7 |

| dk min | 4.3 | 5.3 | 6.3 | 7.3 |

| d1 max | 0.68 | 0.73 | 0.83 | 0.83 |

| d1 min | 0.52 | 0.57 | 0.67 | 0.67 |

| h max | 0.6 | 0.6 | 0.85 | 0.85 |

| h min | 0.5 | 0.5 | 0.75 | 0.75 |

| k max | 1.4 | 1.4 | 1.4 | 1.4 |

| k min | 0.7 | 0.7 | 0.8 | 0.8 |

Lightweight and cost-effective:

High strength internal thread weld studs are typically made from 5000 and 6000 series aluminum alloys. Aluminum forms a natural, dense oxide film in air that provides protection, resulting in lightweight, excellent strength-to-weight ratio, and superior rust resistance. Aluminum's excellent thermal conductivity and low melting point allow for capacitor discharge welding of studs.These studs are widely used in environments requiring lightweight, corrosion-resistant, and high-strength connections.

Anti-rust treatment:

When we ship high strength internal thread weld studs overseas, we usually pack them in strong cartons or wooden crates. Inside, we use VCI paper or bags,those are the ones that help prevent rust. That way, they stay in good shape even during long ocean trips. If you need, we can also do special packaging like bulk bags or put them on pallets. It helps with shipping costs and handling, depending on how many you’re ordering.