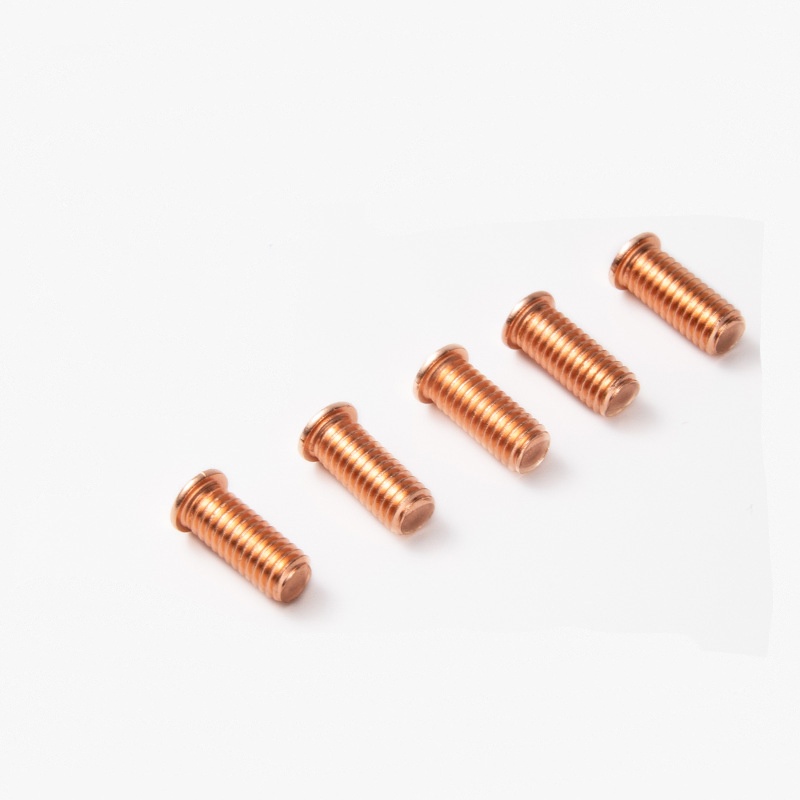

High Precision Internal Thread Weld Studs

Send Inquiry

High precision internal thread weld studs are pretty versatile, which is a big plus. They can break through spatial limitations, such as welding on the top of equipment or vertical surfaces, and can be adapted to a variety of common metals, which also reduces the difficulty of welding components of different materials. During welding, the bottom of the stud will form a tight welding surface, which is widely used in leak-proof scenes such as storage tanks, containers, and piping systems, thus effectively preventing the leakage of liquids or gases.

Strong and pressure-resistant:

Carbon steel high precision internal thread weld studs are the most common and cheapest option. They usually meet standards like ISO 13918 Type 4.4, 4.8, or 5.6. They have excellent sturdiness and can withstand greater external pressure, so they are suitable for most common application scenarios. We also treat the studs with plain color and protective layers such as galvanizing to help extend their service life. Their sturdiness but inexpensive price makes them the first choice for very important uses such as automotive frames, machinery and steel structures.

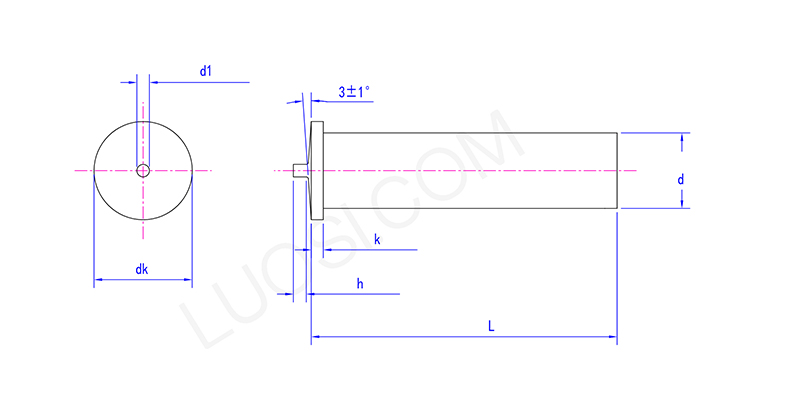

| Mon |

Φ3 |

Φ4 |

Φ5 |

Φ6 |

| d max | 3.1 | 4.1 | 5.1 | 6.1 |

| d min | 2.9 | 3.9 | 4.9 | 5.9 |

| dk max | 4.7 | 5.7 | 6.7 | 7.7 |

| dk min | 4.3 | 5.3 | 6.3 | 7.3 |

| d1 max | 0.68 | 0.73 | 0.83 | 0.83 |

| d1 min | 0.52 | 0.57 | 0.67 | 0.67 |

| h1 max | 0.6 | 0.6 | 0.85 | 0.85 |

| h1 min | 0.5 | 0.5 | 0.75 | 0.75 |

| k max | 1.4 | 1.4 | 1.4 | 1.4 |

| k min | 0.7 | 0.7 | 0.8 | 0.8 |

International quality certification:

We make our high precision internal thread weld studs following strict quality rules that meet ISO 9001:2015 standards. That means all the exported studs have consistent materials, the right sizes, proper strength, and we can track them through every step of making them. If you ask, we’ll give you full certification papers with each shipment, so they meet all the global requirements.