High Efficiency Weld Studs

Send Inquiry

A big reason high efficiency weld studs are good is how fast they are to install,way quicker than drilling and bolting, which cuts down assembly time a lot. Automated stud welding guns can put in hundreds of them an hour, so they’re perfect for high-volume factories, like car or appliance makers. This speed means you save on labor costs and get more done. The process is clean too,no need for pre-drilled holes. That means fewer extra steps and projects get finished faster.

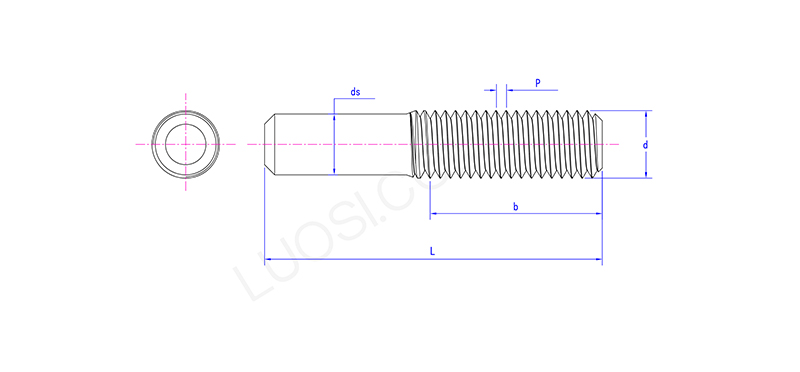

| Mon | M5 | M6 | M8 | M10 | M12 | M14 | M16 |

| P | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 |

| ds | 4.48 | 5.35 | 7.19 | 9.03 | 10.86 | 12.7 | 14.7 |

Advantages:

Highly effective welded studs provide a secure hold. When welded, the base of the stud fuses tightly with the base material, forming a stronger bond than a typical stud or the base metal itself. This allows them to withstand externally applied pressure much better than standard fasteners. This is particularly important for secure structural engineering in earthquake-prone areas. Properly welded studs are incredibly reliable—you can rely on these critical connections, and they make the entire structure stronger.

Can effectively weld galvanized or painted surfaces:

High efficiency weld studs right onto galvanized surfaces needs specific steps because the zinc can vaporize. We suggest using studs made for this or cleaning the area before welding. Paint usually messes with the weld arc. If the surface is painted, you’ve got to get all the paint off the exact spot where you’re welding the stud. That way, you get a strong, reliable metal bond and it works like it should every time.