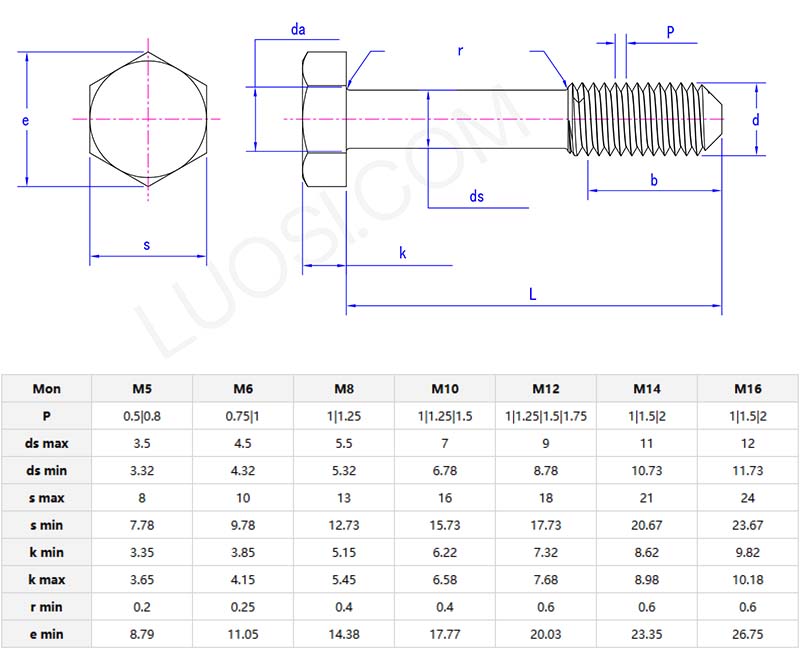

Hexagon Head Screw With Waisted Shank

Send Inquiry

Hexagon head screw with waisted shank is a relatively narrow section (" waist ") between the finger and the threaded part. It reduces weight and material while retaining the hexagonal head, making the bolt easy to tighten with a wrench or socket.

The hexagon head screws with waisted shank has a part without thread. This part is an intermediate transition part, which can enhance the fatigue strength of the screw. It is mainly made of carbon steel, stainless steel and other materials. Stainless steel is corrosion-resistant and rust-resistant, while carbon steel is low in cost and high in strength. The surface coating can be galvanized, blackened, nickel-plated, etc.

Applications and parameters

Mechanics use hexagon head screw with waisted shank in automotive suspensions to absorb road impact. Factory machines rely on them to manufacture adjustable arms or levers. Enthusiasts install them in 3D printers or robots. Even outdoor equipment such as folding tents or bicycle racks uses them to balance rigidity and mobility.

Hexagon head screws with waisted shank can easily help you align and fix uneven surfaces. Its waist has a certain degree of curvature, so you don't need to force the parts to be completely aligned. They are often used in agricultural equipment or old machinery.

Hexagon head screws with waisted shank can be used for the installation of HVAC or plumbing. Its waist handle can reduce the friction of components, such as mechanical joints or adjustable brackets. They are also applied in automobiles, aerospace or construction.

Precautions

Hexagon head screw with waisted shank is not all-purpose fasteners. So please do not use them under pure tensile force. Do not use them to replace full-thread screws in rigid joints, as it will reduce the stability of the waist. In addition, do not use soft materials such as wood or plastic. The handle is most suitable for metal-to-metal installation.