Rugged Hexagonal Bolt

Send Inquiry

Product surface treatment

Surface treatments on Rugged Hexagonal bolt help protect them from rust and can make them last longer in different conditions. A common choice is electro-galvanizing, which puts a thin zinc layer on the bolt. It's a cost-effective way to prevent rust and is good for general industrial use. Hot-dip galvanizing has a thicker zinc coating, so the Hexagonal bolt holds up well in outdoor or harsh conditions like construction and marine settings.

2.Dacromet is a geometric corrosion-resistant treatment that protects Hexagonal bolt well against salt spray and chemicals, making it a good fit for automotive and aerospace uses. Nickel plating can improve the appearance of Rugged Hexagonal bolt and provide moderate corrosion resistance, making it suitable for electronic devices and machinery. For high-demand situations, chrome plating offers better wear resistance and a smoother surface finish.

These treatments don’t just make the Hexagonal bolt last longer—they also ensure reliable performance in various settings, from everyday machinery to critical engineering projects. They shield the Hexagonal bolt from moisture, chemicals, and physical wear.

Product Usage Instructions

To get a good, tight connection with a hex bolt, start by checking that the bolt and nut threads are clean and in good shape.Insert the bolt through the hole, then hand-tighten the nut first. Always use a torque wrench with the correctly sized socket to avoid rounding off the bolt head.Tighten evenly to the recommended value suitable for your specific bolts and work. For areas with strong vibrations, self-locking hex bolts can help prevent loosening.

Q&A Session

How do you make sure your Rugged Hexagonal bolts have accurate dimensions and good thread quality?

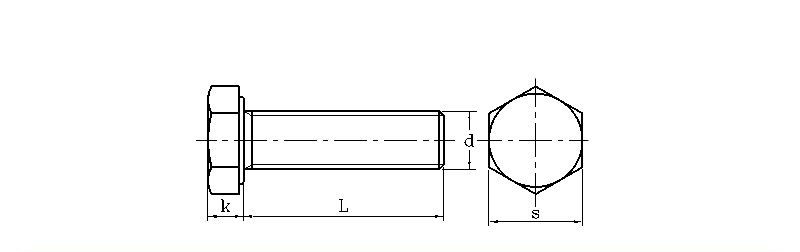

We use advanced cold forging and rolling machines to manufacture each bolt – this helps improve the grain structure and strength. Our quality control includes strict dimensional checks for head size, shank diameter, and length. Also, each bolt goes through thread verification with Go/No-Go gauges. Ensure that the thread pitch and profile match the specified standards, so they can fit with your nuts and assembled parts.

| mm | |||||||

| d | S | k | d | Thread | |||

| max | min | max | min | max | min | ||

| M3 | 5.32 | 5.5 | 1.87 | 2.12 | 2.87 | 2.98 | 0.5 |

| M4 | 6.78 | 7 | 2.67 | 2.92 | 3.83 | 3.98 | 0.7 |

| M5 | 7.78 | 8 | 3.35 | 3.65 | 4.82 | 4.97 | 0.8 |

| M6 | 9.78 | 10 | 3.85 | 4.14 | 5.79 | 5.97 | 1 |

| M8 | 12.73 | 13 | 5.15 | 5.45 | 7.76 | 7.97 | 1.25 |

| M10 | 15.73 | 16 | 6.22 | 6.58 | 9.73 | 9.96 | 1.5 |

| M12 | 17.73 | 18 | 7.32 | 7.68 | 11.7 | 11.96 | 1.75 |

| M14 | 20.67 | 21 | 8.62 | 8.98 | 13.68 | 13.96 | 2 |

| M16 | 23.67 | 24 | 9.82 | 10.18 | 15.68 | 15.96 | 2 |

| M18 | 26.67 | 27 | 11.28 | 11.7 | 17.62 | 17.95 | 2.5 |

| M20 | 29.67 | 30 | 12.28 | 12.71 | 19.62 | 19.95 | 2.5 |