High Torque Hexagonal Bolt

Send Inquiry

High torque hexagonal bolts are super common in construction—they’re the ones holding steel frames, bridges, and prefab buildings together. They keep beams and columns nice and secure. You can also see them everywhere on cars, used to fasten components such as the engine and chassis.hey are also applied in heavy machinery and agricultural equipment because they can withstand strong vibrations and variable loads exceptionally well.They perform reliably under stress and are a type of universal fastener.In numerous engineering and industrial applications, they are trusted to create strong yet detachable connection points, ensuring safety and durability for every project.

Product Material Introduction

The material a hexagonal bolt is made of matters a lot for its performance, how long it lasts, and whether it fits specific environments. The most common hexagonal bolts are made from carbon steel—it balances strength and affordability well for general uses. If you need better corrosion resistance, stainless steel High Torque Hexagonal bolt like grades 304 or 316 are a good choice. They work well in marine, chemical, and food processing industries. When the weather is hot or you need non-magnetic products, people will choose brass or bronze hex bolts.对For more arduous tasks — such as in aerospace or other important projects — people use hex bolts made of high-strength alloys, such as titanium alloy or Inconel alloy.These materials have high strength, moderate weight, and can withstand high temperatures and corrosion exceptionally well

Q&A Session

Which international standards do you high-torque hex bolts comply with?What intensity levels are available for selection?

Our high-torque hex bolts meet common international standards—stuff like ISO 4014, ISO 4017, DIN 933, DIN 931, and ASTM A307. When it comes to strength grades, we’ve got classes 4.8 and 8.8. We also carry the higher-strength ones: 10.9 and 12.9. Each bolt has a clear mark for easy identification. That way, you get the right, certified product for your specific structural or machinery needs, and it ensures safety and performance.

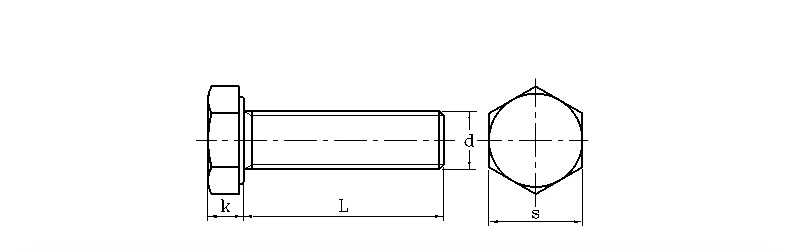

| mm | |||||||

| d | S | k | d | Thread | |||

| max | min | max | min | max | min | ||

| M3 | 5.32 | 5.5 | 1.87 | 2.12 | 2.87 | 2.98 | 0.5 |

| M4 | 6.78 | 7 | 2.67 | 2.92 | 3.83 | 3.98 | 0.7 |

| M5 | 7.78 | 8 | 3.35 | 3.65 | 4.82 | 4.97 | 0.8 |

| M6 | 9.78 | 10 | 3.85 | 4.14 | 5.79 | 5.97 | 1 |

| M8 | 12.73 | 13 | 5.15 | 5.45 | 7.76 | 7.97 | 1.25 |

| M10 | 15.73 | 16 | 6.22 | 6.58 | 9.73 | 9.96 | 1.5 |

| M12 | 17.73 | 18 | 7.32 | 7.68 | 11.7 | 11.96 | 1.75 |

| M14 | 20.67 | 21 | 8.62 | 8.98 | 13.68 | 13.96 | 2 |

| M16 | 23.67 | 24 | 9.82 | 10.18 | 15.68 | 15.96 | 2 |

| M18 | 26.67 | 27 | 11.28 | 11.7 | 17.62 | 17.95 | 2.5 |

| M20 | 29.67 | 30 | 12.28 | 12.71 | 19.62 | 19.95 | 2.5 |