Hexagon Head Bolts With Wire Holes

Send Inquiry

Hexagon head bolts with wire holes look like standard hexagon bolts, but there are several small holes drilled in its head. This way, wires or cables can be passed through multiple bolts. They are very easy to install and are often used in machinery, motorcycles or outdoor equipment, etc.

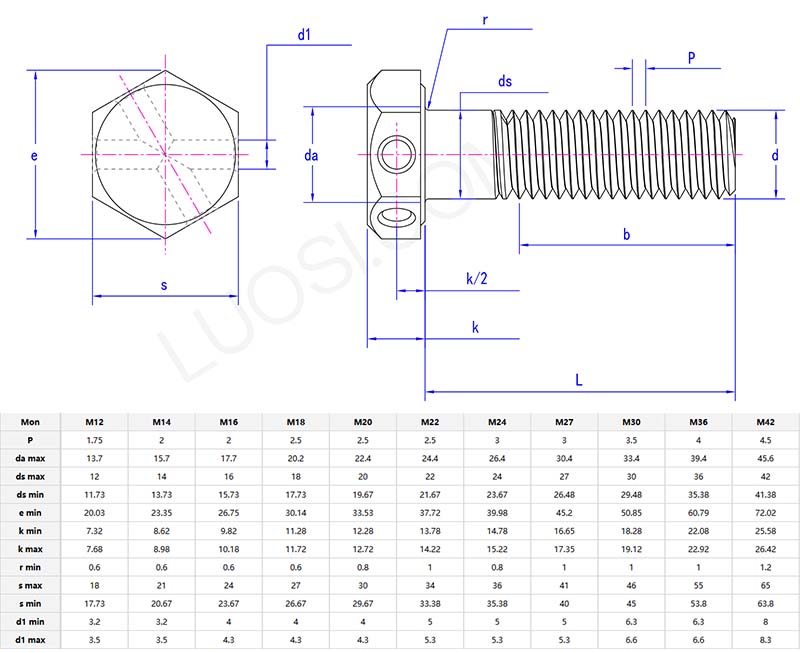

Features and parameters

Hexagon head bolts with wire holes have solved the problem that bolts remain tight in a high-vibration environment. By passing the steel wire through the holes of the adjacent bolts, a "lock" can be formed to prevent the bolts from loosening. This is cheaper and simpler than using special anti-loosening nuts or adhesives. They are used to fix bicycle parts, aircraft panels or engine components that shake frequently.

Hexagon head bolt with wire hole locking can be seen everywhere. Motorcycle brake calipers use them to ensure safety on rough roads; Aircraft maintenance personnel fixed the bolts to the maintenance panel with steel wire. Farmers use them on tractors to prevent components from loosening. Amusement park equipment also relies on them to prevent tampering.

For ship rigging or sailing ship hardware, hexagon head bolt with wire hole can withstand the invasion of seawater and storms. Pass the marine-grade steel wire through the bolt holes, and a fail-safe connection can be formed on the mooring piles, mast fittings or railings to prevent loosening.

Installing tips

Installing hexagon head bolts with wire holes requires two steps. First of all, they need to be tightened properly with a wrench. Then, pass the metal wire through the hole in a pattern (such as an "8" shape) that connects multiple bolts. Twist the two ends of the metal wire together with pliers to fix all the components in place. The use of crimping sleeves can make the surface neater.

Product Packaging

We package these fasteners just to keep them safe during shipping and storage—no extra unnecessary stuff. First off, we put them into thick, moisture-proof plastic bags. Each bag has a set number of pieces, usually 50 or 100, so it’s easy for you to count and use them right away. Then we put these bags into sturdy corrugated cardboard boxes. Every box has a clear label stuck on the outside, listing basic details like size, quantity, and batch number. For small orders, we seal the boxes up tight with strong tape to stop them from popping open while being shipped. For bulk orders, we stack the cardboard boxes on wooden pallets, then wrap the whole stack with stretch film to keep everything steady and prevent shifting around. If you’re worried about rust when storing them, we can also throw a small desiccant bag into each plastic bag if you ask for it. The packaging is simple but works well, and if you need custom packaging—like labels printed with your company info—you can talk to us about that too.

Q&A Session

Question: Can Reduced hexagon head bolts with wire holes be customized with different thread lengths or coatings according to our needs?

Answer: Yeah, we do full customization for Reduced Shank Hexagon Head Bolt. You can tell us exactly what you need—like thread length (partial or full thread), coating type (zinc plating, hot-dip galvanizing, Dacromet, and so on), even non-standard shank diameters. Our engineering team will go over all the design details with you first, just to make sure the customized Reduced Shank Hexagon Head Bolt fits your exact use case. We’ll also send you samples of the customized Reduced Shank Hexagon Head Bolt for you to check and approve before we start mass production.