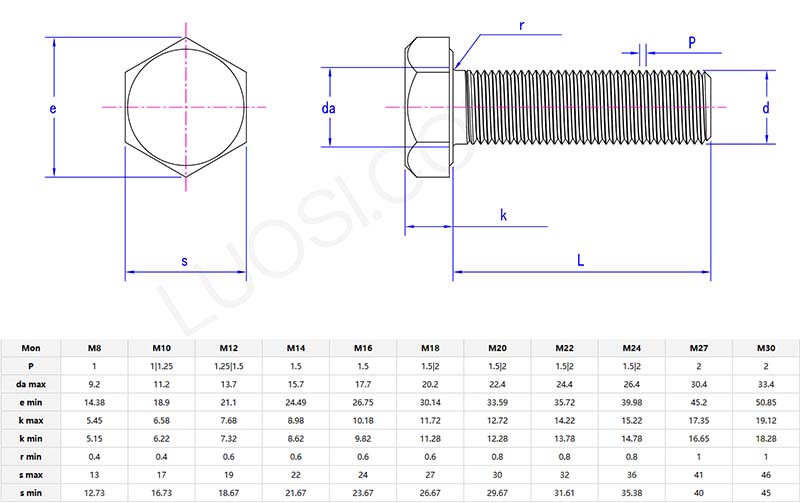

Hexagon Head Bolts With Fine Pitch Thread

Send Inquiry

Compared with standard bolts, hexagon head bolts with fine pitch thread have a tighter thread spacing, allowing for more precise adjustments and better clamping of thin walls. These bolts are typically used in mechanical, automotive parts or electronic products and are shock-resistant.

Product details and parameters

The application scope of hexagon head bolts with fine pitch thread is very wide. For example, automotive engines, CNC machine tools or aerospace equipment, etc. They are used for the connection between thin metal plates and also for custom motorcycles or 3D printers, etc.

Fine pitch thread hexagon head bolts can be used to repair car engines or gearboxes. They are usually used on components such as valve covers, timing systems or sensor brackets. They can enhance the stability between the connectors and will not scratch the edges.

When manufacturing motorcycles or all-terrain vehicles, fine pitch thread hexagon head bolts can ensure the safety and stability of key components. Fine thread can prevent the handlebars, exhaust pipes or suspension components from loosening due to vibration. They are used for furniture or cabinets that require polished surfaces. Because fine thread can reduce the cracking of hardwood or composite materials, and the hexagonal head is flush with the bolt, the surface is smooth and beautiful.

Fine Pitch vs. Coarse Thread: Why It Matters

Hexagon head bolts with fine pitch thread are used where coarse thread cannot be used. Coarse-threaded installation is faster, but it is not firm enough to grip in hard materials such as steel or titanium. Fine-threaded threads distribute the load to more threads, thereby reducing the risk of spalling or shearing.