Corrosion Resistant Stainless Steel Wire Rope

Send Inquiry

Corrosion Resistant Stainless Steel Wire Ropes are indispensable tools in ship and marine engineering operations. In ship berthing and offshore platform operations, they are used to make or equip mooring ropes, rigging and towing cables.

With its natural resistance to saltwater corrosion, it performs significantly better than carbon steel rope in these harsh environments, solving the shortcoming of carbon steel rope being susceptible to corrosion in such scenarios. Even if it is constantly exposed to sea spray, humidity, or ultraviolet radiation, the Corrosion-Resistant Stainless steel wire rope can maintain its structure and tensile strength. This is extremely important because in critical marine operations, it is not allowed to malfunction - only then can long-term safety and reliability be ensured.

Product Advantages

In the aerospace and defense industries, we use high-performance Corrosion Resistant Stainless Steel Wire Ropes to manufacture components such as control systems, parachute devices, and cargo fixation devices.

The specific grades we use, such as 304 or 316, are excellent choices because they offer high strength, corrosion resistance, and reliability, even under extreme pressure conditions. These Corrosion-Resistant Stainless steel wire ropes are precisely manufactured and must perform perfectly in these critical applications. If a failure occurs here, the consequences could be very serious. Therefore, the quality of these materials and whether they have formal certification are particularly important - only with these can we ensure that the work can be completed and people are safe.

Excellent corrosion resistance

The biggest advantage of this Corrosion Resistant Stainless Steel Wire Rope is that it is not afraid of rust. It is very strong and durable when used at the seaside, in chemical plants or in open air. Unlike galvanized steel, corrosion-resistant stainless steel wire ropes, by adding chromium as a key alloying element, can spontaneously form a dense passive oxide film on the surface. This film effectively isolates corrosive media, thus providing excellent corrosion resistance. It also offers an aesthetic appeal and maintains strength in harsh environments, though it generally has a higher initial cost but longer service life.

Product Parameters

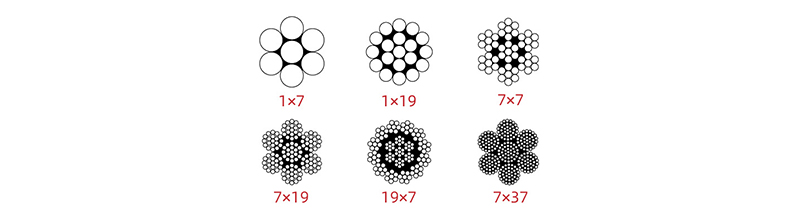

|

Product structure |

Specification(mm) |

Reference weight(100m/KG) |

Safe Load Weight(KG) |

Maximum Load Bearing Capacity(KG) |

|

7x7 |

0.5 | 0.10 | 5.4 | 16.3 |

| 0.8 | 0.25 | 13.9 | 41.6 | |

| 1 | 0.39 | 21.7 | 65.0 | |

| 1.2 | 0.56 | 31.2 | 93.6 | |

| 1.5 | 0.88 | 48.8 | 146.3 | |

| 1.8 | 1.26 | 70.2 | 210.7 | |

| 2 | 1.56 | 86.7 | 260.1 | |

| 2.5 | 2.44 | 135.5 | 406.4 | |

| 3 | 3.51 | 195.1 | 585.2 | |

| 4 | 6.24 | 346.8 | 1625.5 | |

| 5 | 9.75 | 541.8 | 1625.5 | |

| 6 | 14 | 780.5 | 2340.7 | |

|

7x19 |

1 | 0.39 | 19.9 | 59.6 |

| 1.2 | 0.56 | 28.6 | 85.8 | |

| 1.5 | 0.88 | 44.7 | 134.1 | |

| 1.8 | 1.26 | 64.4 | 193.1 | |

| 2 | 1.56 | 79.5 | 238.4 | |

| 2.5 | 2.44 | 124.2 | 372.5 | |

| 3 | 3.51 | 178.8 | 536.4 | |

| 4 | 6.24 | 317.9 | 953.6 | |

| 5 | 9.75 | 496.7 | 1490.1 | |

| 6 | 14 | 715.2 | 2145.7 | |

| 8 | 25 | 1199.7 | 3599.0 | |

| 10 | 39 | 1874.5 | 5623.5 | |

| 12 | 56.2 | 2699.3 | 8097.8 | |

| 14 | 76.4 | 3674.0 | 11022.0 | |

| 16 | 100 | 4798.7 | 14396.1 | |

| 18 | 126.4 | 6073.3 | 18220.0 | |

| 20 | 156 | 7498.0 | 22493.9 | |

| 22 | 189 | 9072.5 | 27217.6 | |

| 24 | 225 | 10797.1 | 32391.2 | |

| 26 | 264 | 12671.6 | 38014.7 | |

|

|

|

|||

| Note |

1.The safe load-bearing capacity for cargo is one-third of the maximum load-bearing capacity, and the safe load-bearing capacity for passengers is one-fifth of the maximum load-bearing capacity. |

|||

| 2.Due to different production batches, there may be errors between the actual dimensions and the table. The data in this table is for reference only. | ||||