Corrosion Resistant Internal Thread Weld Studs

Send Inquiry

The materials used for corrosion resistant internal thread weld studs are strictly controlled. We strictly adhere to ISO 13918 in production to ensure product quality. For example, processing 4.8 carbon steel according to ISO 13918 ensures reliable strength, toughness, and corrosion resistance, reducing the occurrence of safety accidents, ensuring the safety of equipment and personnel, and minimizing customer losses due to quality issues.

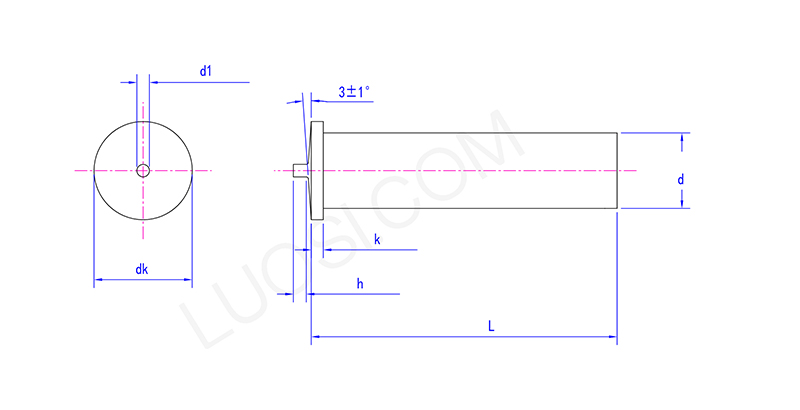

| Mon |

Φ3 |

Φ4 |

Φ5 |

Φ6 |

| d max | 3.1 | 4.1 | 5.1 | 6.1 |

| d min | 2.9 | 3.9 | 4.9 | 5.9 |

| dk max | 4.7 | 5.7 | 6.7 | 7.7 |

| dk min | 4.3 | 5.3 | 6.3 | 7.3 |

| d1 max | 0.68 | 0.73 | 0.83 | 0.83 |

| d1 min | 0.52 | 0.57 | 0.67 | 0.67 |

| h max | 0.6 | 0.6 | 0.85 | 0.85 |

| h min | 0.5 | 0.5 | 0.75 | 0.75 |

| k max | 1.4 | 1.4 | 1.4 | 1.4 |

| k min | 0.7 | 0.7 | 0.8 | 0.8 |

Install:

It’s really important to install corrosion resistant internal thread weld studs properly,using calibrated stud welding equipment and the right settings, like current, time, and lift. That way, they’ll hold up. The bond formed by welding is permanent and requires no regular maintenance. Maintaining the threaded area clean to avoid damage will facilitate nut installation. If the fastener is coated, it is recommended to regularly inspect the coating for wear. Targeted maintenance can effectively extend the life of the stud. As for the welded area, which is permanent, there is no need for excessive attention.

Discounted prices:

The price of corrosion resistant internal thread weld studs depends a lot on how much the base metal costs,like steel, stainless steel, or aluminum. Since raw material prices change a lot and are traded worldwide, our quotes for weld studs usually only stay good for a short time, maybe 7 to 14 days. We try to keep prices steady, but if the market shifts a lot,We try to keep prices stable, but market conditions force us to adjust, even for large orders or long-term collaborations.